Web: www.welding-honest.com Whatsapp:+86 13252436578

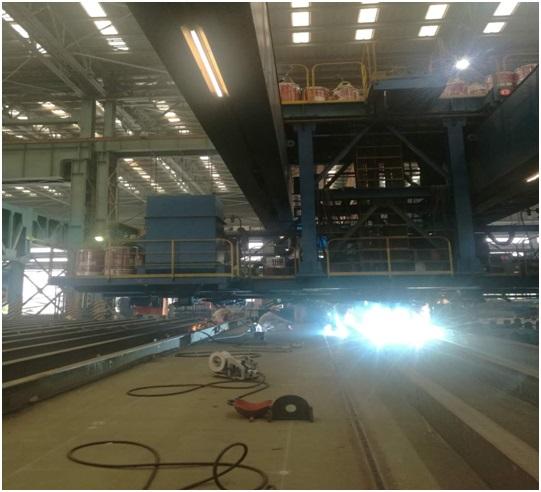

Mukushanda kwekugadzira ngarava, mabhiriji, zvivakwa zvesimbi uye mamwe maindasitiri, kazhinji kune marefu-ekona-kurudyi welds akaiswa, uye otomatiki welding inonyanya kushandiswa, ine trolleys ewelding, otomatiki welding maoko uye mamwe anoshanda akawanda-electrode welding nzira.Kune T-row multi-electrode welding, kambani yedu yakatanga GFL-70C iron powder type flux cored wire ine GCL-11G simbi poda mhando welding waya, iyo iri kutambirwa nevatengi vakawanda.Iyi welding yekubatanidza nzira ine yakakwira welding kumhanya, yakanakisa zinc poda-resistant primer, uye yakanaka weld bead kuumbwa.Kugona kwekuisa kwewaya yekumberi GCL-11G kwakakwira kusvika 97%, kunyanya nekuda kwehuwandu hwesimbi yekuzadza, uye waya yekumashure GFL-70C inovimbisa kuumbwa kweiyo weld bead, uye kumhanya kwewelding kunogona kusvika 1000-1400mm. /min.Iyo inonyanya kukodzera kune flat welding uye flat fillet welding yezvimiro zvakasiyana sengarava, mabhiriji, michina, mota uye zvivakwa zvesimbi.

Multi-electrode T-row yakakwirira-kumhanya uye inobudirira welding

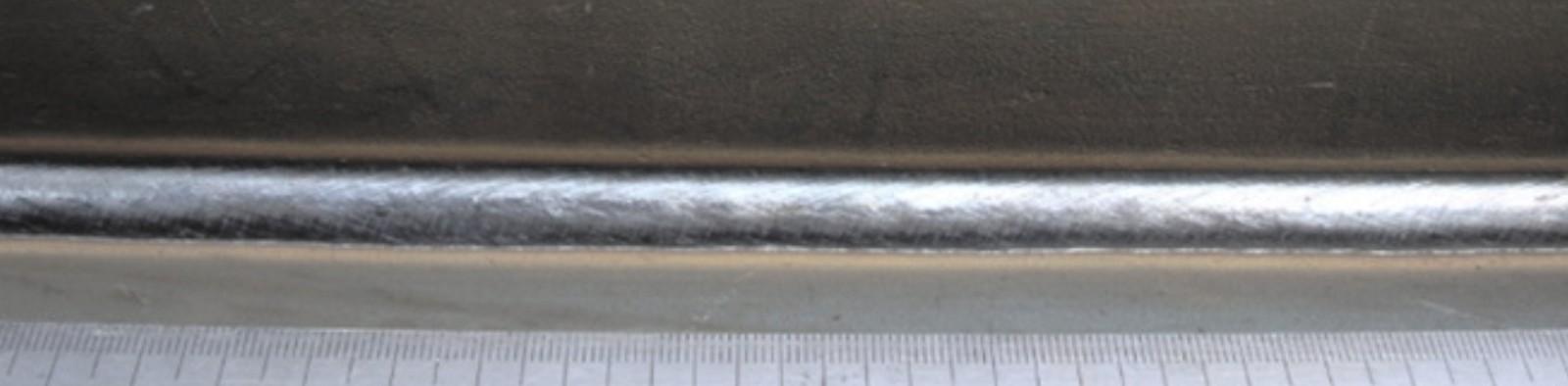

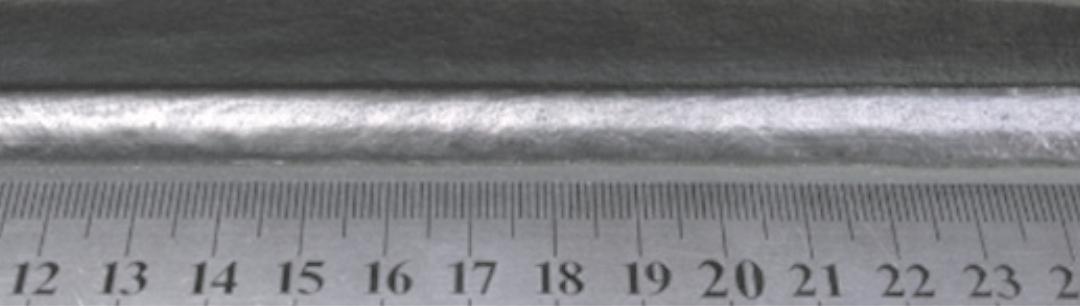

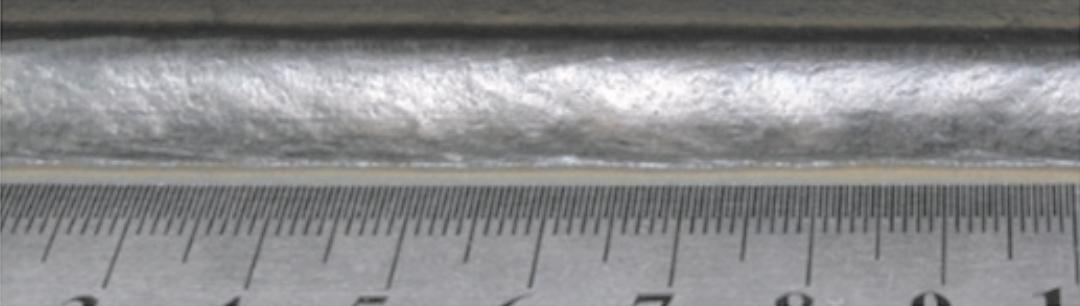

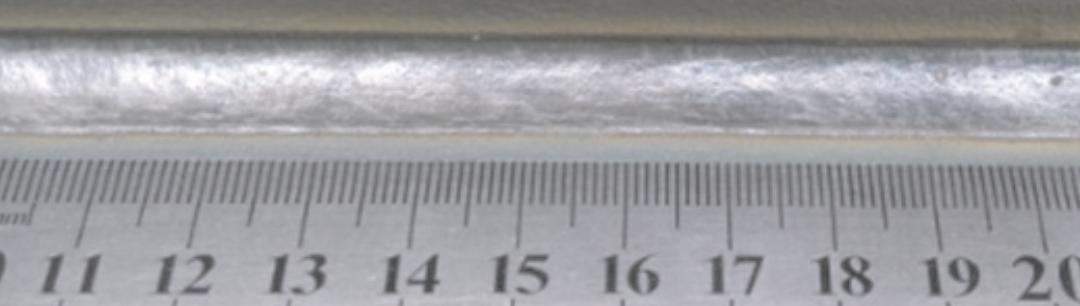

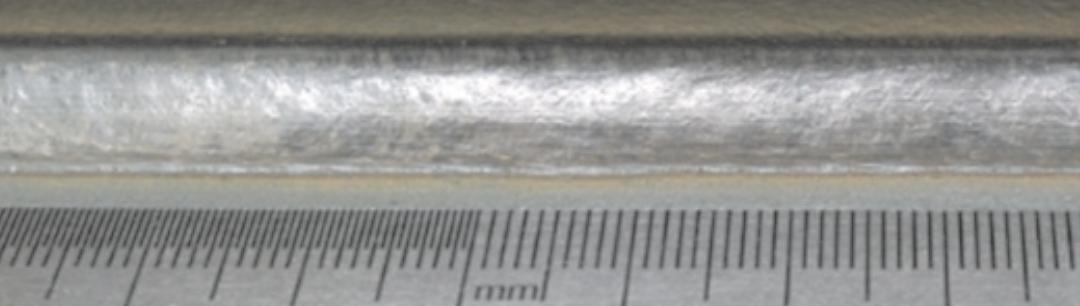

Kuonekwa kwe weld slag kubviswa

Tisati deslagging

Mushure mekudzikisa

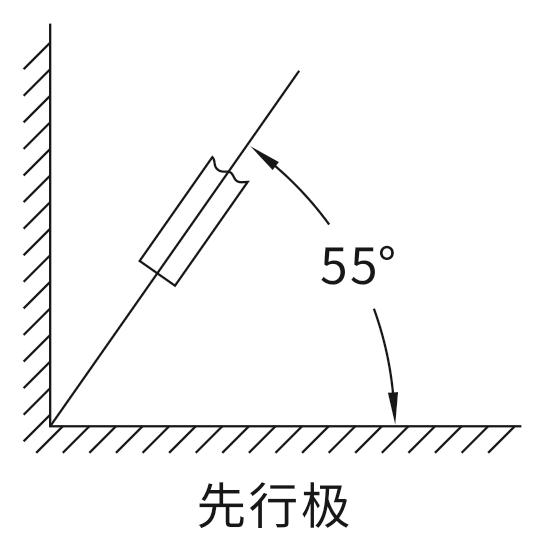

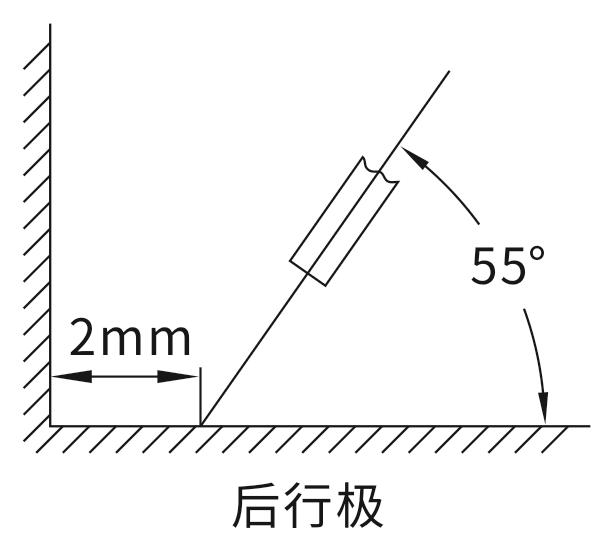

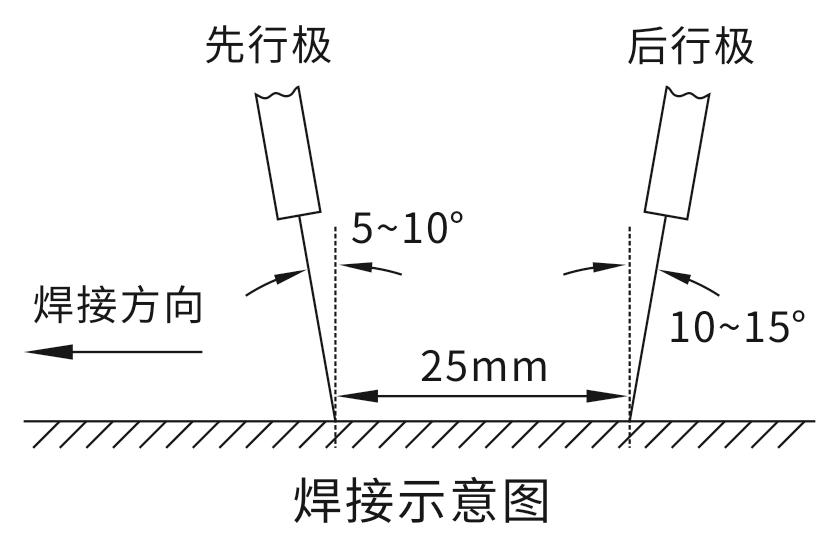

Chinhu chikuru cheiyi nzira yewelding ndeyekunyanya kushanda kwayo, multi-electrode welding panguva imwe chete, uye hapana chikonzero chekunetseka pamusoro pekukanganiswa kwe polarity uye magnetic field.Boka rega rega remafillet welds rine masheti maviri ematochi emagetsi, uye boka rega rega rine waya dzemberi nekumashure.Iyo yekumberi waya ine zvirinani porosity kuramba uye inoshanda seyakakura yakawanda yekuzadza simbi.Waya yekumashure inongoda kuve nechokwadi chekuti weld bead yakaumbwa sandara, yunifomu uye yakachena.Hunhu huripo hwesimbi hupfu mhando flux cored wire, sewaya yekumashure yemusanganiswa uyu, inogona kungosangana nezvinodiwa zvekuenderana kwayo chimiro uye chitarisiko.Iyo welding torch angle uye kuremerwa kwechinhambwe cheiyi nzira yewelding inoratidzwa mumufananidzo uri pazasi:

Hybrid yakanyanya kumhanya fillet welding:

Ongorora: Gadzirisa chinhambwe chiri pakati pewaya dzemberi nedzokumashure zvichienderana nekupisa chaiko kwedziva rakanyungudutswa panguva yewelding.

Iyi welding nzira inogona kuwana inodiwa welding tarisiro nekugadzirisa akasiyana welding paramita.Nekugadzirisa welding ikozvino, voltage, welding kumhanya, welding torch kureba, nezvimwewo, akasiyana welding angle saizi anogona kuwanikwa.

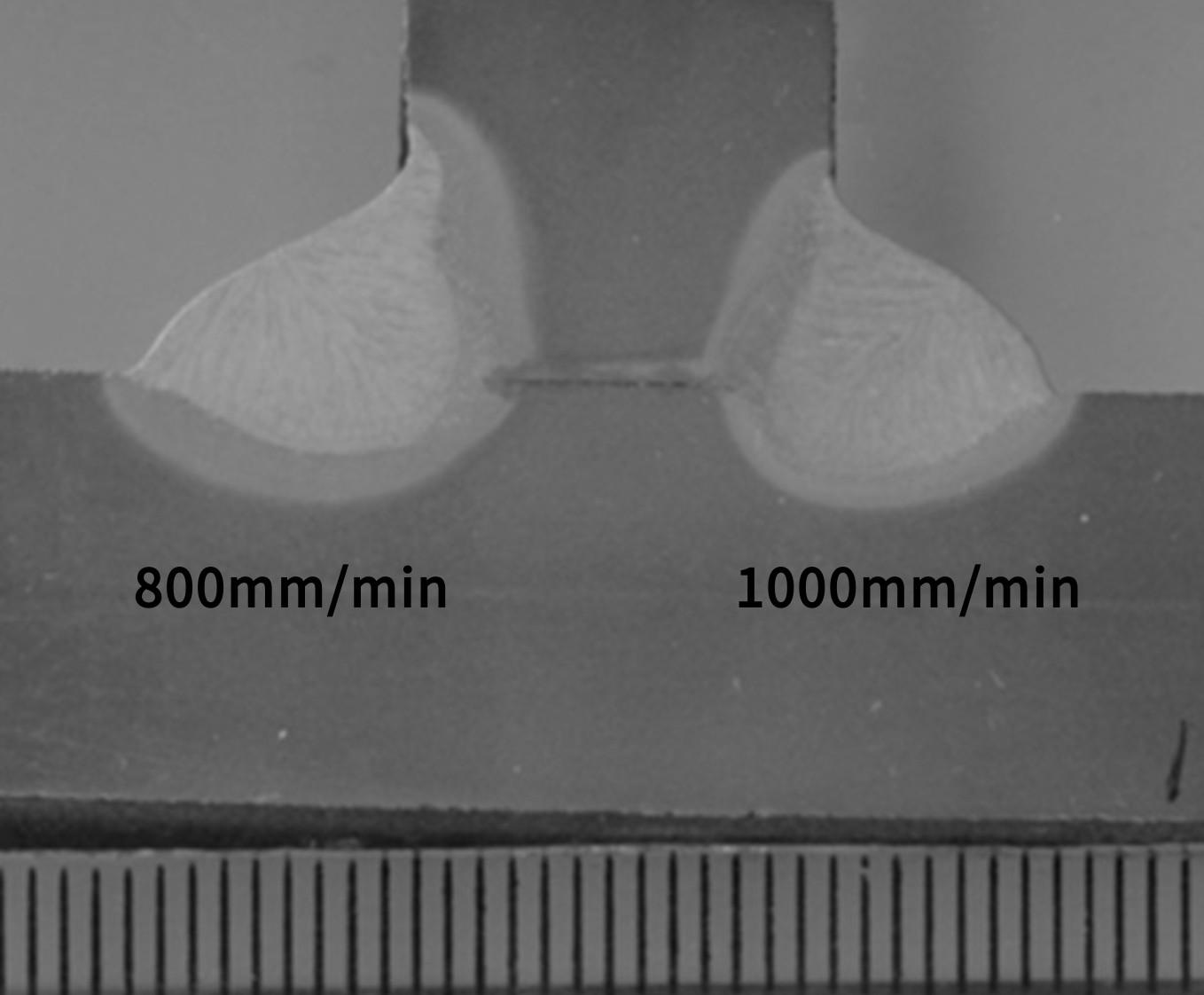

Yakasanganiswa yakanyanya kumhanya fillet welding muenzaniso 1

GCL-11G (advanced electrode)/GFL-70C (rear electrode) 1.4mm:

| Ikozvino uye voltage | welding speed mm/min | Solder gumbo kureba |

| Pioneer 360A/32V Kutevera kirasi 360A/38V Electrode spacing 25MM | 800 | 9-10 |

| 1000 | 7-8 |

| kureba kwetsoka | 9.0 | kureba kwetsoka | 7.0 | |

| Convexity | 0.4 | Convexity | 0.8 | |

| Kupinda | 2.0 | Kupinda | 2.2 |

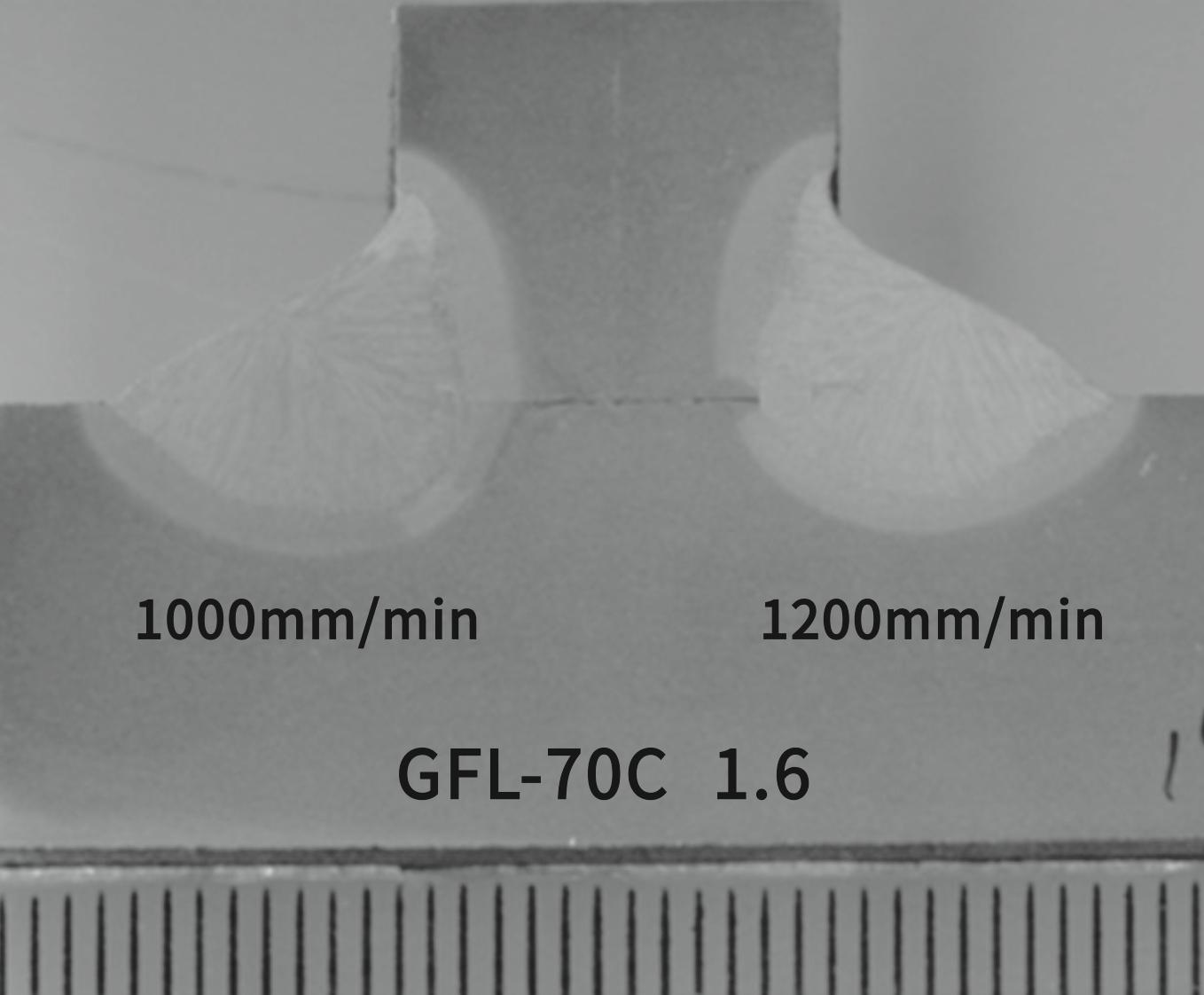

Yakasanganiswa yakanyanya kumhanya fillet welding muenzaniso 2

GCL-11G (advanced electrode)/GFL-70C (rear electrode) 1.6mm:

| Ikozvino uye voltage | welding speed mm/min | Solder gumbo kureba |

| Pioneer 360A/32V Kutevera kirasi 360A/38V Electrode spacing 25MM | 1000 | 8-9 |

| 1200 | 7-8 |

Kuonekwa kwekupinda

| kureba kwetsoka | 8.0 |

| kureba kwetsoka | 7.0 |

| Convexity | 0 | Convexity | 0.3 | |

| Kupinda | 2.4 | Kupinda | 2.7 |

GCL-11G+GFL-70C welding mamiriro ekurudziro

| Welding chikamu | Tsanangudzo mm | welding tsanangudzo | welding speed mm/min | Solder gumbo saizi mm | Remark | |

| Sirika yepamberi | Back silk | |||||

| musanganiswa | 1.4 | 350-400A 32-36V | 320-380A 36-38V | 700- 1000 | 5-8 | Iyo yekumberi waya ndeyeGCL-11G, inonyanya kushandiswa pakuzadza, yakakwirira ikozvino, yakaderera voltage;waya yekumashure iGFL-70C, high voltage, low current |

| 1.6 | 360-420A 36-38V | 320-400A 36-38V | 1000- 14000 | 5-8 | ||

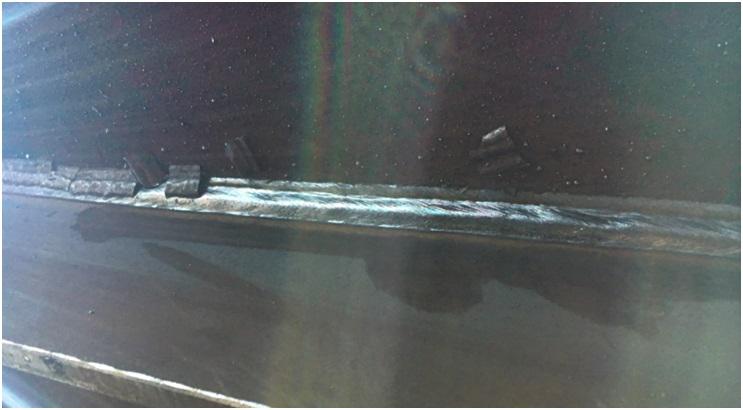

Imwe: 9-12mm welding angle inogona kuwanikwa nekugadzirisa chaiyo welding torch angle uye welding kumhanya.Weld bead sezvinoratidzwa pasi apa:

12mm hombe welding angle

Kune iyi welding nzira, ndokumbirawo uteedzere anotevera welding kurudziro uye dziviriro

1. Chenesa marara, ngura, mavara emafuta, uye zvisaririra zveoxidation, zvikasadaro zvinogona kukonzera pores kana kuremara sekuumbwa kwakashata.

2. Yakawandisa mhute yemvura inogadzirisa ichakanganisa kunaka kwewelding uye kukonzera pores.Kana hunyoro hwakakwirira, dehumidification yakakodzera inofanira kuitwa isati yaputirwa, uye imwe-sided overnight welding inofanira kudziviswa.

3. Kukora kwefirimu repende kunowanzodzorwa pa15-35um.Kana iyo pendi firimu ukobvu yakanyanya kukora, inokonzeresa pores nyore, uye inoda kukwenenzverwa kana zvichidikanwa.

4. Kuyerera kwegasi kunodzorwa pa 20-25l / min, iyo yakaoma elongation inodzorwa inenge 20 ~ 25mm, uye mhepo inomhanya inopfuura 2m / s, uye hugaro hunodiwa hunodiwa.

5. Kana wasanganiswa welding:

(1) Iyo yekumberi waya GCL-11G welding simba pani inosarudza iyo yakasimba giya, uye yekumashure waya GFL-70C welding power panel inosarudza giya repakati;

(2) Kana welding fillet welds, rimwe nerimwe boka re quadrupoles rinoitwa nenzira yekutarisana netambo dzemberi uye kumashure.

Zviri pamusoro ndezvekungotaura chete, ndapota inzwa wakasununguka kundijekesera kana pane zvisina kufanira.

More information send E-mail to export@welding-honest.com

Nguva yekutumira: Zvita-20-2022