Whatsapp:+8613252436578 E-mail:sale@welding-honest.com

1. kupatsanura

Zvinoenderana nehuwandu hwekabhoni yemukati, kabhoni simbi inogona kukamurwa muzvikamu zvitatu zvinotevera:

1) Yakaderera kabhoni simbi C% ≤ 0.25

2) Medium kabhoni simbi 0.25

3) High carbon simbi C%> 0.6

Low Carton

Mid-Carbon

High-Carbon

2. weldability kuongorora

Huwandu hwekabhoni yemukati ireferensi yakakosha yekuvandudzwa kwemaitirwo ewelding.Sezvo iyo kabhoni yemukati inowedzera, simba uye kuoma kunowedzera, nepo plastiki uye kuoma kunoderera, uku kushushikana kunowedzera.Zvichienderana, iyo yakadzikira iyo kabhoni yemukati, iyo iri nani iyo weldability, saka, iyo kabhoni yemukati ndiyo chiyero chekutonga kuoma kwekabhoni simbi welding, uye akasiyana welding maitiro anofanirwa kutorwa kune akasiyana kabhoni.

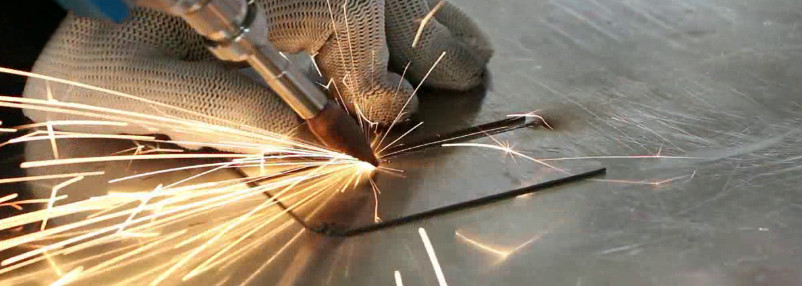

3. Welding process

Kusarudzwa kwekabhoni simbi welding zvinhu kunotevera musimboti we "simba rakaenzana"

1. Low carbon steel (inowanzozivikanwa sesimbi yakapfava)

Magiredhi esimbi akajairwa akadai seQ235 (yaimbozivikanwa seA3 simbi), Q255, nezvimwewo, kazhinji haitore matanho akakosha kana welding, kana preheating kana postheating.

2. Medium carbon steel

Inowanzoshandiswa simbi yakadai 30 #, 45 #, nezvimwewo, 45 # ndiyo zvinhu zvekugadzira saw blades uye mafaira, zviri nani kushandisa yakaderera-hydrogen welding zvinhu pamwe zvakanaka mutswe kuramba, preheating 100-200 ° C;Kana zvisingaite preheat, Cr-Ni austenitic Stainless steel welding material inogona kusarudzwa.

3. High carbon steel

Inowanzo shandiswa simbi mamakisi akadai 60Si2Mn, T8, T10 uye zvichingodaro.60Si2Mn isimbi yakajairwa yechitubu, kazhinji haiite welding kurapwa, inowanzo shandiswa se-welding, inofanira kunge iri 250-350 ° C preheating, welding inofanira kurohwa kuti ibvise kushushikana, uye 650 ° C post-heat kurapwa, inogona zvakare. sarudza Cr-Ni austenitic Stainless steel welding zvinhu

Yechina, yakapfava simbi ruoko electrode general welding zvakakosha:

Electrode drying tembiricha

| Item | Ganda rudzi | Product | Tembiricha | Nguva |

| Yakaderera kabhoni simbi uye yakakwirira simba simbi | Low hydrogen mhando | E7016、E7048、E7015、E7015-G | 300-350 ℃ | 60min |

| E7015,E8015-G,E9016-G,E9015-D1、E10015-D2、E12015-G | 330-380 ℃ | |||

| High kuoma uye yakaderera hydrogen mhando | E7016-G,E7015-G,E8015-G,E9015-G,E10015-G | 350-380 ℃ | 60min | |

| Iron poda yakaderera hydrogen mhando | E7018、E7018-1 | 300-350 ℃ | 60min | |

| E8018-G,E918-G,E9018-M、E10018-D2、E10018M、E11018-G、E11018M、E12018-G | 350-380 ℃ | 60min |

2. Unyoro, mafuta, ngura, nezvimwewo pamusoro pezvinhu zvehwaro zvinofanira kubviswa

3. Shandisa nzira yekudzokera kumashure kuti weld kudzivirira stomata painotangira

Short arc welding inofanira kushandiswa, senge oscillating mitsetse, uye oscillation amplitude haifanire kudarika katatu dhayamita yewaya.

Nguva yekutumira: Oct-13-2022