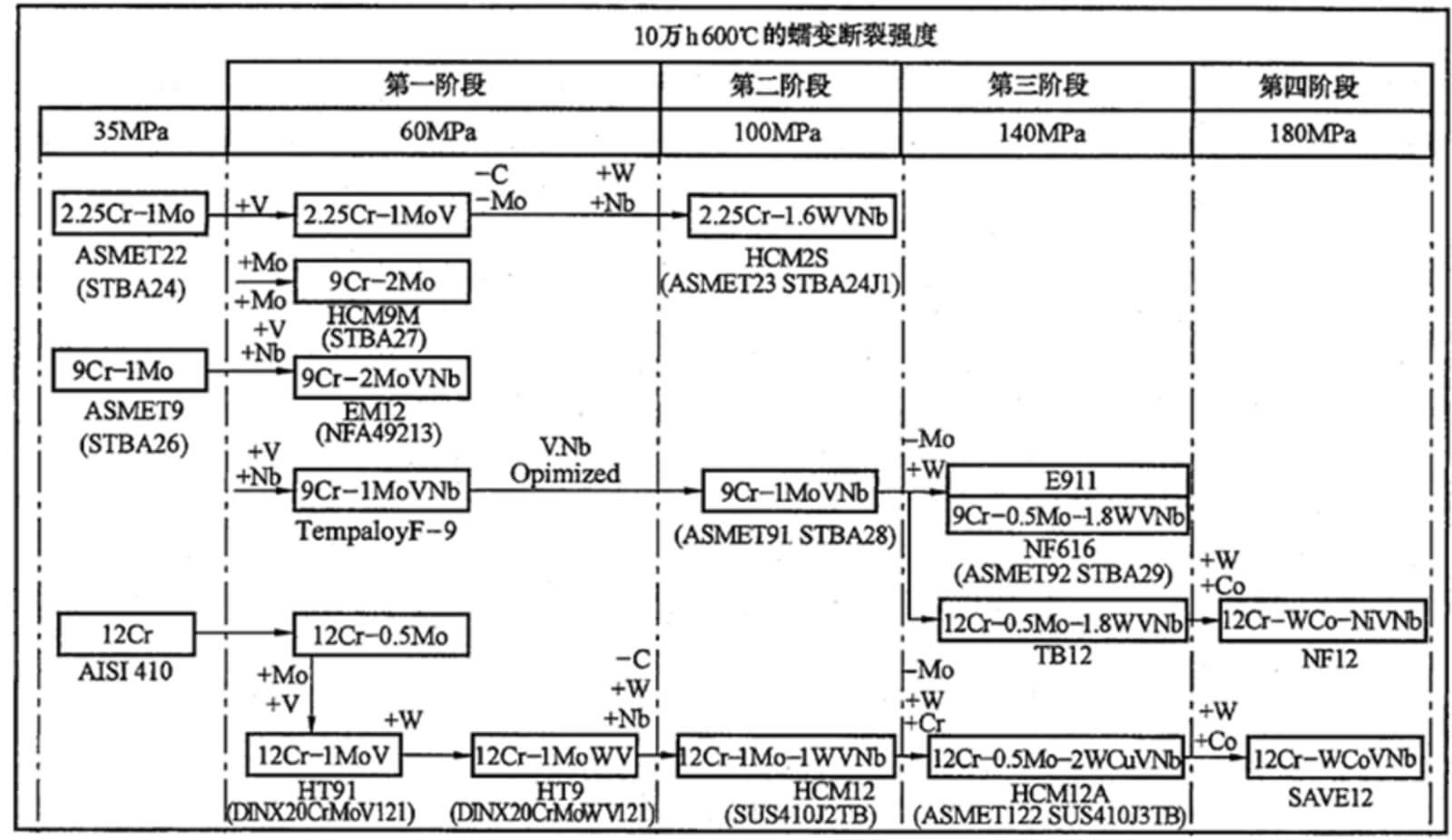

Kuvandudzwa kweferritic heat-resistant simbi

Wedzera Cr-1.25Cr kusvika 12Cr

Wedzera V, Nb, Mo, W, Co, nezvimwe.

Kuvandudza maitiro e ferritic heat-resistant simbi

Cherechedza:

Zvinoenderana nemaitiro epasi rese, izvo zvinodaidzwa kuti pearlite, bainite, uye martensitic isingadziviriri simbi mumaboiler nemapombi masimbi anounganidzwa pamwe chete anonzi "ferritic heat-resistant steels".

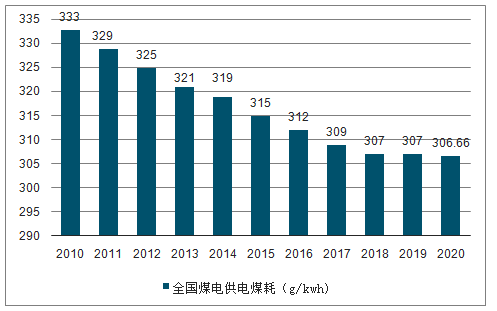

Nekugadziriswa kwesimba renyika yangu uye optimization yekuvaka kwemagetsi ekuvaka, yakakwirira-inoshanda, yakachena, uye ine hushamwari hukuru-hukuru uye yakakwirira-parameter zvikamu zvave kutonga.Nekuwedzera maparamita eutsi (kudzvanywa uye tembiricha), inogona kunyatso kuvandudza kupisa kweiyo unit, kuderedza kushandiswa kwemarasha, uye kuderedza CO2 kubuda.Parizvino, nzira huru yekuvandudza kushanda kwemagetsi emagetsi ekupisa ndeyekuvandudza maparamita eutsi uye kugadzira supercritical (SC) uye Ultra-supercritical (USC) zvikamu.Parizvino, kune anopfuura 100 miriyoni-kilowatt ekupedzisira-supercritical (USC) mayunitsi akaiswa mukushanda munyika yangu, ari ekutanga pasirese muhuwandu uye huwandu hwakazara.

Statistics uye Forecast yeMarasha Kushandiswa kweMarasha Power Supply muChina kubva 2010 kusvika 2020

2.Main Chromium Molybdenum Steel Welding Rod Products

Tafura 2 Kuratidzwa kwemaitiro emumiririri pearlitic kupisa-resistant simbi maelectrodes

| Item | Main ingredient | Kupisa℃*H | Mechanical maitiro | ||||

| Yield Mpa | Tensile Mpa | Wedzera % | Shock J/℃ | ||||

| GER-107 | 0.5%Mo | 620*1 | 477 | 570 | 24.0 | 152/0 | - |

| GER-207 | 0.5%Cr-0.5%Mo | 690*1 | 490 | 590 | 23.0 | 143/0 | - |

| GER-307 | 1.25%Cr-0.5%Mo | 690*1 | 490 | 590 | 23.0 | 146/0 | - |

| GER-317 | 1.25%Cr-0.5%Mo-V | 730*2 | 541 | 635 | 22.5 | 166/0 | - |

| GER-407 | 2.25%Cr-1%Mo | 690*1 | 586 | 682 | 21.0 | 142/0 | - |

| GER-417 | 2.25%Cr-1%Mo-V | 720*8 | 556 | 657 | 21.0 | 145/-18 | 120/-30 |

| GER-507 | 5%Cr-0.5%Mo | 740*1 | 490 | 605 | 23.0 | 124/0 | - |

Cherechedza:

1. Kambani yedu yakagadzira EXXXX-15, EXXXX-16, EXXXX-18 uye mamwe e-coating slag akatevedzana emagetsi egiredhi rimwechete kuti asangane nemisika yakasiyana yekuda.Izvo zviri pamusoro zvinongoratidza kushanda kweEXXXX-15 electrodes.

3.2 Rondedzero ye subcritical uye yepamusoro (yekupedzisira) yakakosha ferritic/martensitic inodzivirira kupisa simbi maelectrodes

| ITEM | STANDARD | Main Character |

| GER-707 | AWS A5.5 E8015-B8 GB/T 5118 E6215-9C1M | 9% Cr-1% Mo Carbon simbi yepakati waya, iyo huru alloy kuumbwa inoshandurwa kubva pakuputira, inokodzera thermal simba subcritical units, A213-T9, A335-P9 simbi welding (yehupfumi uye inoshanda, yakanaka kugadzirwa) |

| GER-91 Core type | AWS A5.5 E9015-B91 GB/T 5118 E6215-9C1MV | 9% Cr-1% Mo-Nb-vn Inokodzera kupisa magetsi akakosha mayuniti, T / P 91 simbi welding, iyo huru alloy kuumbwa kunotamiswa kubva kune welding core, yakanyanya tembiricha microstructure uye kugadzikana kwekuita. |

| GER-91M mushonga ganda musimboti | 9% Cr-1% Mo-Nb-VN Inokodzera kupisa magetsi akakosha mayuniti, T / P 91 simbi welding, iyo huru alloy kuumbwa inotamiswa kubva kune welding core, yakanyanya tembiricha microstructure uye kugadzikana kwekuita. | |

| GER-92 Core type | AWS A5.5 E9015-B92 | 9% Cr-0.5% Mo-WV-Nb-N Inokodzera thermal simba supercritical units, T / P 92 simbi welding, iyo huru alloy kuumbwa inoshandurwa kubva kune yakakosha waya, yakanyanya tembiricha microstructure uye kugadzikana kwekuita. |

| GER-93 | Chiyero chedu | 9% Cr-3% W-3% Co-Cu-V-Nb-B Yakakodzera kusungirirwa kwepamusoro yakakwira supercritical G115 simbi yekugadzira magetsi ekupisa.Iine chimiro chakanaka uye kugadzikana kwekuita pakupisa kwepamusoro.Simba rinogara riri 1.5 nguva yeP92 simbi, uye kuramba kwayo kune yakanyanya kupisa tembiricha oxidation uye corrosion iri nani pane iyo yeP92 simbi. |

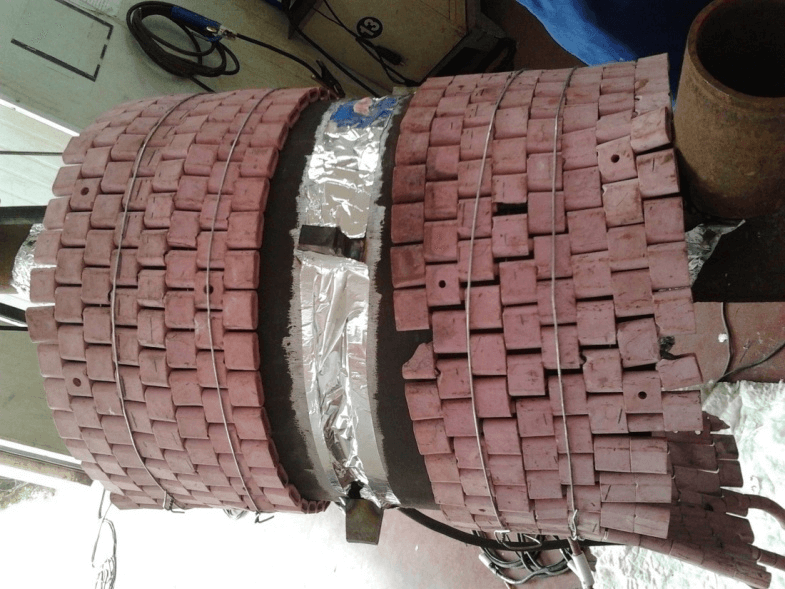

Electrode performance display

| Item | Main ingredient | Kupisa℃*H | Mechanical maitiro | |||

| Yield Mpa | Tensile Mpa | Wedzera % | Shock J | |||

| GER-707 | 9%Cr-1%Mo | 740*1 | 540 | 670 | 24.0 | 119.7 |

| GER-91 | 9%Cr-1%Mo-Nb-VN | 760*2 | 557 | 702 | 21.0 | 96.3 |

| GER-91M | 9%Cr-1%Mo-Nb-VN | 760*2 | 553 | 701 | 22.5 | 81.0 |

| GER-92 | 9%Cr-0.5%Mo-WV-Nb-N | 760*2 | 596 | 706 | 21.5 | 103.0 |

| GER-93 | 9%Cr-3%W-3%Co | 770*4 | 580 | 720 | 20.0 | 77.7 |

Cherechedza:

1. GER-91M iri kupfeka shanduko, ndiko kuti, iyo welding core ndiyo yakajairwa kabhoni simbi core waya, uye iyo huru alloy inoshandurwa nekupfeka.Kuenzaniswa neGER-91 (core wire transition type), ine mabhenefiti ari nani ehupfumi uye ndiyo yedu yepamusoro Zvigadzirwa zvikuru zvewelding tsvimbo kune supercritical thermal simba.

3.The 2015 version ye ASME standard inoda E9015-B91 electrode Mn + Ni≤1.4%, uye 2017 version inoda ≤1.2% yesimbi yepasi.(2021 yazvino vhezheni yeASME inoenderera mberi nekushandisa iyo 2015 vhezheni yeASME yekuumbwa zvinodiwa zveE9015-B91/ B92 electrodes).Kuti zvizadzise kudiwa kwemusika, yedu E9015-B91 uye E9015-B92 welding rods dzakagadzira mhando mbiri dzezvinhu zvinoenderana newelding: Mn+Ni≤1.4% uye Mn+Ni≤1.2%.Nekuti iyo yekupedzisira ine yakawanda musika kudiwa, zviri pamusoro zvinoratidza 91/ 92 maelectrode akaiswa simbi Mn+Ni≤1.2%.

4. Kuratidzira kwekuongorora kwemaitiro e-ultra-supercritical electrodes

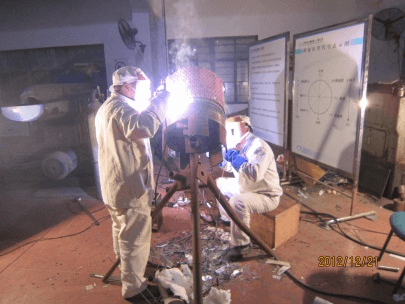

4.1 Maitiro ekufanirwa kweP91/92 welded joints

6. Zvakanakira uye hunhu hwedu kupisa-resistant simbi electrodes nokuda chrome-molybdenum simbi.

1. Kune marudzi akawanda uye marudzi ose

●Kuumbwa kunotangira pa0.5%Mo kusvika pa9%Cr-3%W-3%Co.

●Shandisa tembiricha kubva pa500℃ kusvika pa650℃.

●Mavara akasiyana-siyana ekuputira uye marudzi ekuputira (EXXXX-15, EXXXX-16, EXXXX-18) anogona kushandiswa kune zvakasiyana-siyana (general type, yakasimba arc force type yemapombi ekuvaka magetsi).

● Inogona kusangana nezvinodiwa zvekushongedza zvezvizhinji zveCr-Mo steels.

2. Kuita kwakanaka

Yakanakisa michina zvivakwa, yakanaka yepamusoro tembiricha kuita (yakanyanya tembiricha inokwira uye yakanyanya tembiricha kuchembera zvivakwa).

3. Unyanzvi hwakanaka

Iyo electrode ine yakanakisa manufacturability munzvimbo dzese, yakagadzikana arc combustion, yakanaka kuomarara uye kuvhuvhuta simba, diki spatter, yakanaka fluidity, yakanaka weld chimiro, uye nyore kubvisa slag mushure mekugadzira.

4. Indasitiri inotungamira

Yakabatana neSuzhou Institute of Thermal Engineering, uye yakapasa ongororo ye "T/P 91/92 Localization Appraisal Meeting" muna 2015, uye yakabatana nemasimba makuru edzimba akadai seShenhua Guohua neGeneral Iron uye Steel Research Institute kugadzira 650 ° C. G115 simbi inotsigira welding zvinhu uye maitiro, uye yakabata akati wandei welding consumables misangano yekutsinhana.

More information send to E-mail: export@welding-honest.com

Nguva yekutumira: Zvita-27-2022