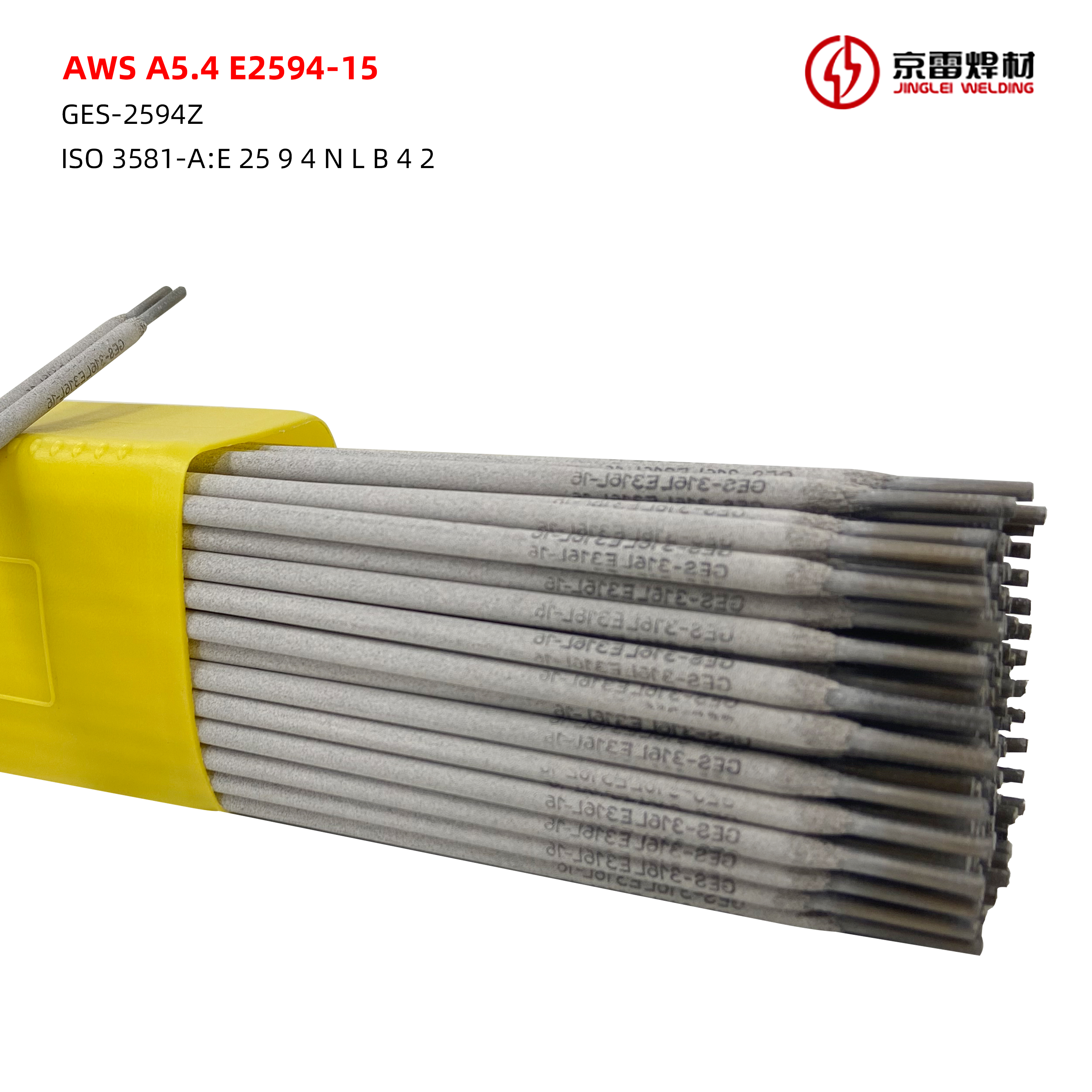

Stainless Steels Manual Electrode E2594-15 GXHY methanol dehydration tower electrode

WEDDING TECHNOLOGY

Usarega mibvunzo

Ramba uchikushungurudza

Arc kusagadzikana

Kuumba kusingataridzike

Yakawandisa spatter

Inokodzera welding ye duplex Stainless simbi

ine 25% Cr, yakadai se0022 crni7mo4n03cr25ni6mo3cu2n, nezvimwe.

Yakaderera hydrogen kaviri chikamu Stainless simbi ruoko electrode, chikuru chikamu 25.5Cr-10Ni-4Mo-0.25N

Ripple zvakanaka

Iyo weld simbi ndeye austenitic uye ferritic biphase

chimiro, uye iyo corrosion resistance index is PRE> 40

Iine simba rakakwirira uye kumira kwakanaka kwegomba uye kushungurudza corrosion cracking.

Yakanakisa welding tekinoroji, yakagadzikana arc, yakanaka kuumbwa, yakapfava ripple, diki splash, nyore kubviswa slag.

Easy slagging

Product Parameter

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | P | S | Ni | Cr | Mo | Cu | Zvimwe |

| GB/T RULES | 0.033 | 1.05 | 0.76 | 0.019 | 0.011 | 9.1 | 25.5 | 3.9 | 0.11 | N:0.24 |

MECHANICAL PROPERTY:

| PROPERTY | KUNYANYA SIMBA(MPa) | KUWEDZERA SIMBA(MPa) | IMAPACT VALUE J/℃ | Kurapa kwekupisa °C*h | ||||

| GB/T RULES | 918 | 22 | - | - | ||||

AKAKUDZWA WEDDING PARAMETERS:

| DIAMETERS ZVINOTAURWA(mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| ELECTRICITY (Amp) | H/W | 30-55 | 50-85 | 80-120 | 100-150 | 140-180 | ||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | - | |||||

Rutsigiro rwefekitari

Chigadzirwa chacho chakakodzera a

zvakasiyana-siyana zvekushandisa

WEDDING TECHNOLOGY

-

Welding zvinhu zvemotokari dzenjanji

Harbin yemagetsi matatu gedhi CMT

-

CJ50 jack-up drill

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | P | S | Ni | Cr | Mo | Cu | Zvimwe |

| GB/T RULES | 0.033 | 1.05 | 0.76 | 0.019 | 0.011 | 9.1 | 25.5 | 3.9 | 0.11 | N:0.24 |

MECHANICAL PROPERTY:

| PROPERTY | KUNYANYA SIMBA(MPa) | KUWEDZERA SIMBA(MPa) | IMAPACT VALUE J/℃ | Kurapa kwekupisa °C*h | ||||

| GB/T RULES | 918 | 22 | - | - | ||||

AKAKUDZWA WEDDING PARAMETERS:

| DIAMETERS ZVINOTAURWA(mm) | 2.0*250 | 2.6*300 | 3.2*350 | 4.0*350 | 5.0*350 | |||||

| ELECTRICITY (Amp) | H/W | 30-55 | 50-85 | 80-120 | 100-150 | 140-180 | ||||

| O/W | 20-50 | 45-80 | 70-110 | 90-135 | - | |||||