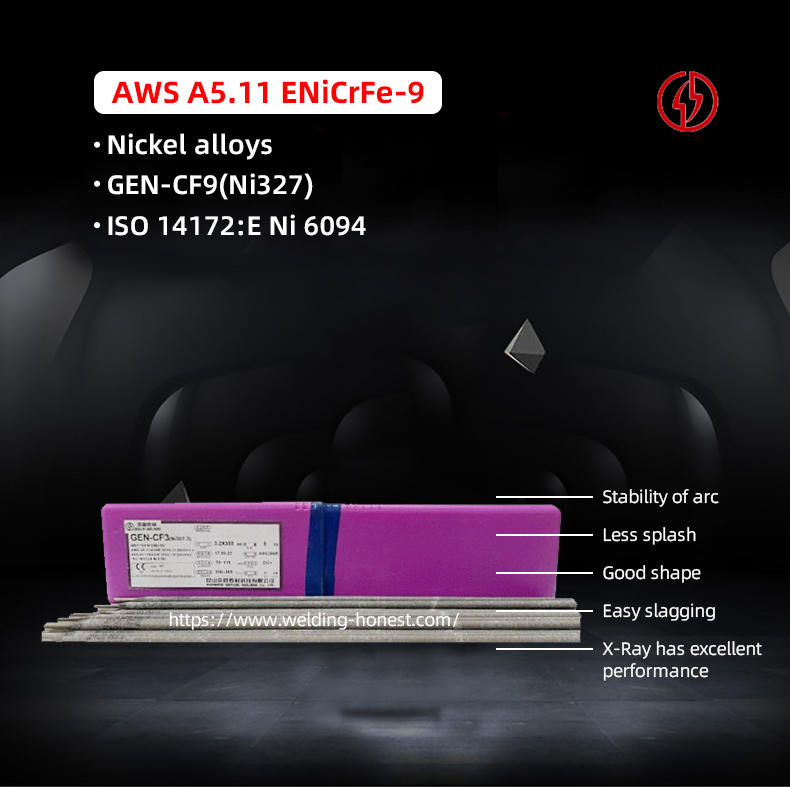

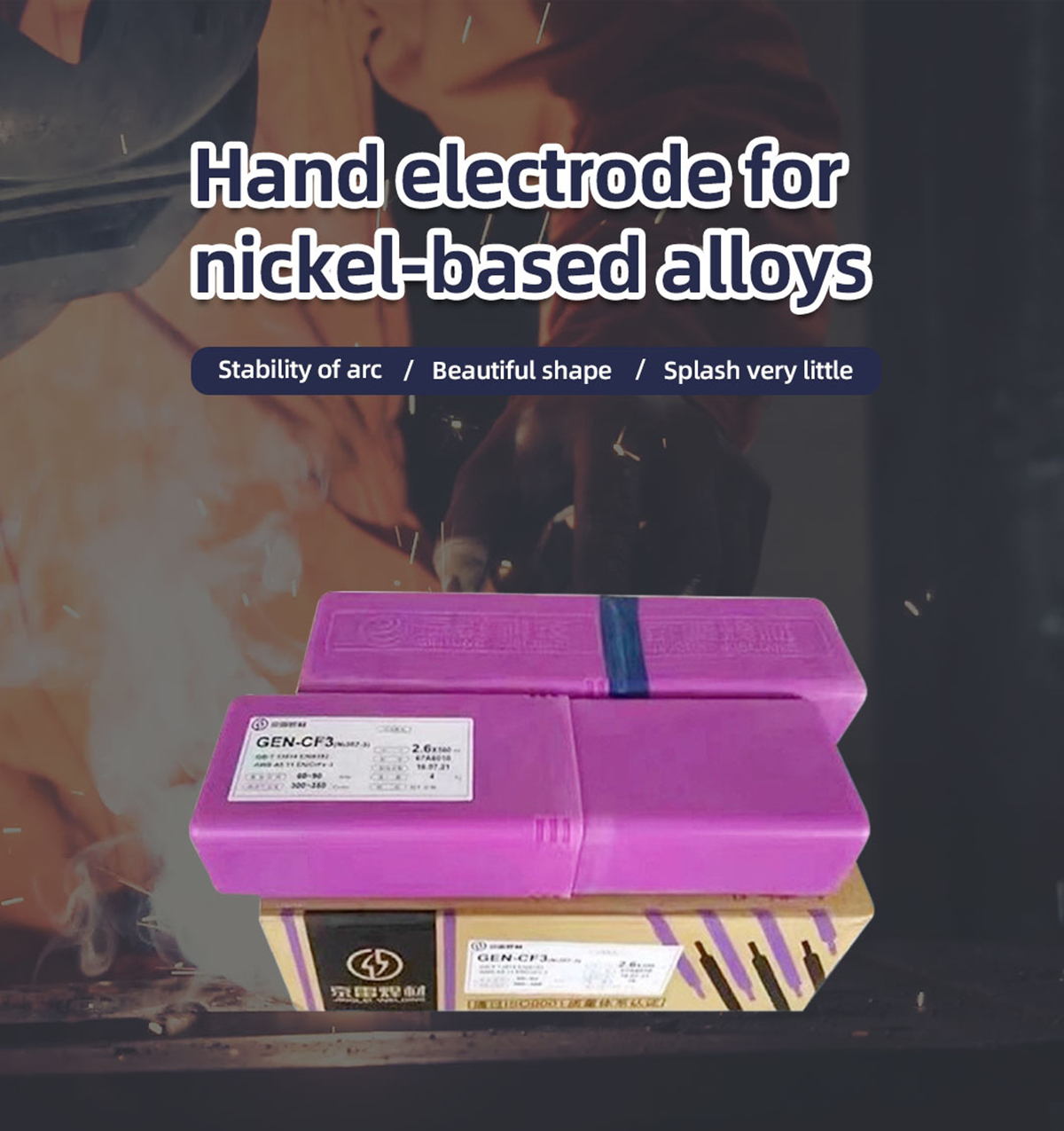

Nickel alloys Manual electrode ENiCrFe-9 Welding kugadzira

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Fe | Cr | Ni | Mo | Cu | Nb+Ta | |

| GB/T RULES | 0.15 | 1.0-4.5 | 0.80 | 12.00 | 12.0-17.0 | ≥55 | 2.5-5.5 | 0.50 | 0.5-3.0 | |

| AWS Mitemo | 0.15 | 1.0-4.5 | 0.75 | 12.00 | 12.0-17.0 | ≥55 | 2.5-5.5 | 0.50 | 0.5-3.0 | |

| MUENZANISO VALUE | 0.07 | 2.6 | 0.28 | 4.03 | 14.3 | 66.6 | 4.41 | 0.060 | 1.67 | |

MECHANICAL PROPERTY:

| PROPERTY | KUNYANYA SIMBA(MPa) | KUWEDZERA SIMBA(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 360 | 650 | - | 18 | ||||

| AWS Mitemo | - | 650 | - | 25 | ||||

| MUENZANISO VALUE | 460 | 680 | - | 41.5 | ||||

AKAKUDZWA WEDDING PARAMETERS:

| DIAMETERS ZVINOTAURWA(mm) | 2.6*300 | 3.2*350 | 4.0*350 | ||||||||

| ELECTRICITY (Amp) | H/W | 69-95 | 70-115 | 95-145 | |||||||

| O/W | 55-80 | 65-110 | 80-130 | ||||||||

Yakaderera hydrogen mhando ruoko electrode, zita kuumbwa (muzana nekurema) iri Ni14Cr4FeNbMo, nickel - chromium - iron alloy electrode.

Yakagadzika arc, yakanaka kuumba, diki splash, nyore kubviswa slag.

Yakanaka porosity kuramba, iyo michina yesimbi yakanyungudutswa yakagadzikana.

-

Nanjing Chengzhi Yongqing Energy 07MnNiMoDR simbi ethylene bhora tangi

Reactor internals

-

Arctic LNG-2 chirongwa

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Fe | Cr | Ni | Mo | Cu | Nb+Ta | |

| GB/T RULES | 0.15 | 1.0-4.5 | 0.80 | 12.00 | 12.0-17.0 | ≥55 | 2.5-5.5 | 0.50 | 0.5-3.0 | |

| AWS Mitemo | 0.15 | 1.0-4.5 | 0.75 | 12.00 | 12.0-17.0 | ≥55 | 2.5-5.5 | 0.50 | 0.5-3.0 | |

| MUENZANISO VALUE | 0.07 | 2.6 | 0.28 | 4.03 | 14.3 | 66.6 | 4.41 | 0.060 | 1.67 | |

MECHANICAL PROPERTY:

| PROPERTY | KUNYANYA SIMBA(MPa) | KUWEDZERA SIMBA(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | 360 | 650 | - | 18 | ||||

| AWS Mitemo | - | 650 | - | 25 | ||||

| MUENZANISO VALUE | 460 | 680 | - | 41.5 | ||||

AKAKUDZWA WEDDING PARAMETERS:

| DIAMETERS ZVINOTAURWA(mm) | 2.6*300 | 3.2*350 | 4.0*350 | ||||||||

| ELECTRICITY (Amp) | H/W | 69-95 | 70-115 | 95-145 | |||||||

| O/W | 55-80 | 65-110 | 80-130 | ||||||||

Nyora meseji yako pano ugotitumira