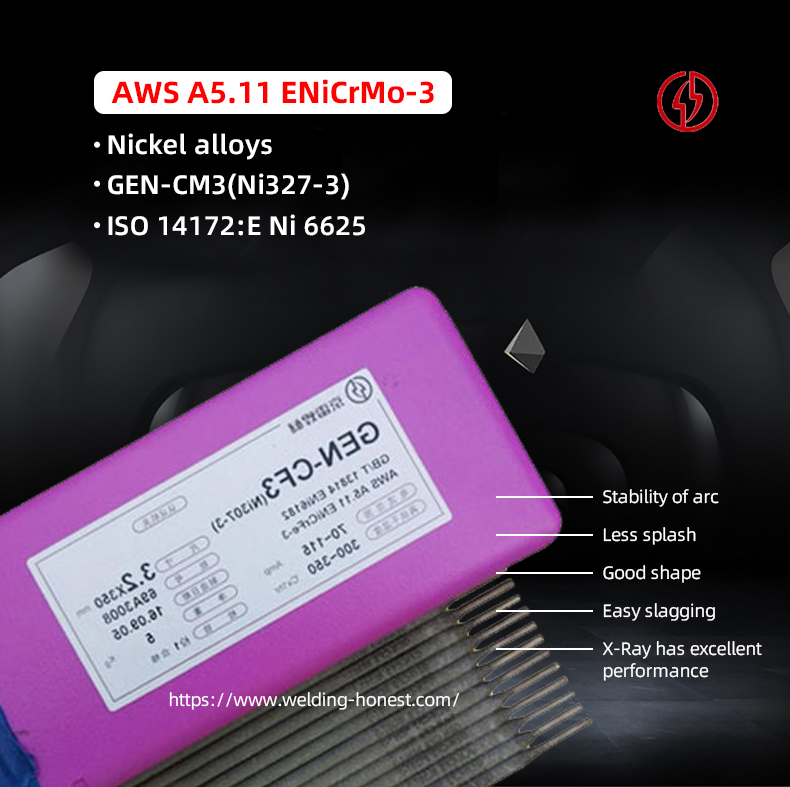

Nickel alloys TIG ERNiCrMo-3 Soldering zvinhu

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | Fe | Nb+Ta | P | S |

| GB/T RULES | 0.10 | 0.50 | 0.50 | 20.0-23.0 | ≥58 | 8.0-10.0 | 5.0 | 3.0-4.2 | - | - |

| AWS Mitemo | 0.10 | 0.50 | 0.50 | 20.0-23.0 | ≥58 | 8.0-10.0 | 5.0 | 3.15-4.15 | 0.02 | 0.015 |

| MUENZANISO VALUE | 0.006 | 0.15 | 0.12 | 22.02 | 64.84 | 8.75 | 0.18 | 3.49 | 0.001 | 0.001 |

MECHANICAL PROPERTY:

| PROPERTY | KUNYANYA SIMBA(MPa) | KUWEDZERA SIMBA(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | - | - | - | - | ||||

| AWS Mitemo | - | - | - | - | ||||

| MUENZANISO VALUE | - | 790 | 159/-196 | 46 | ||||

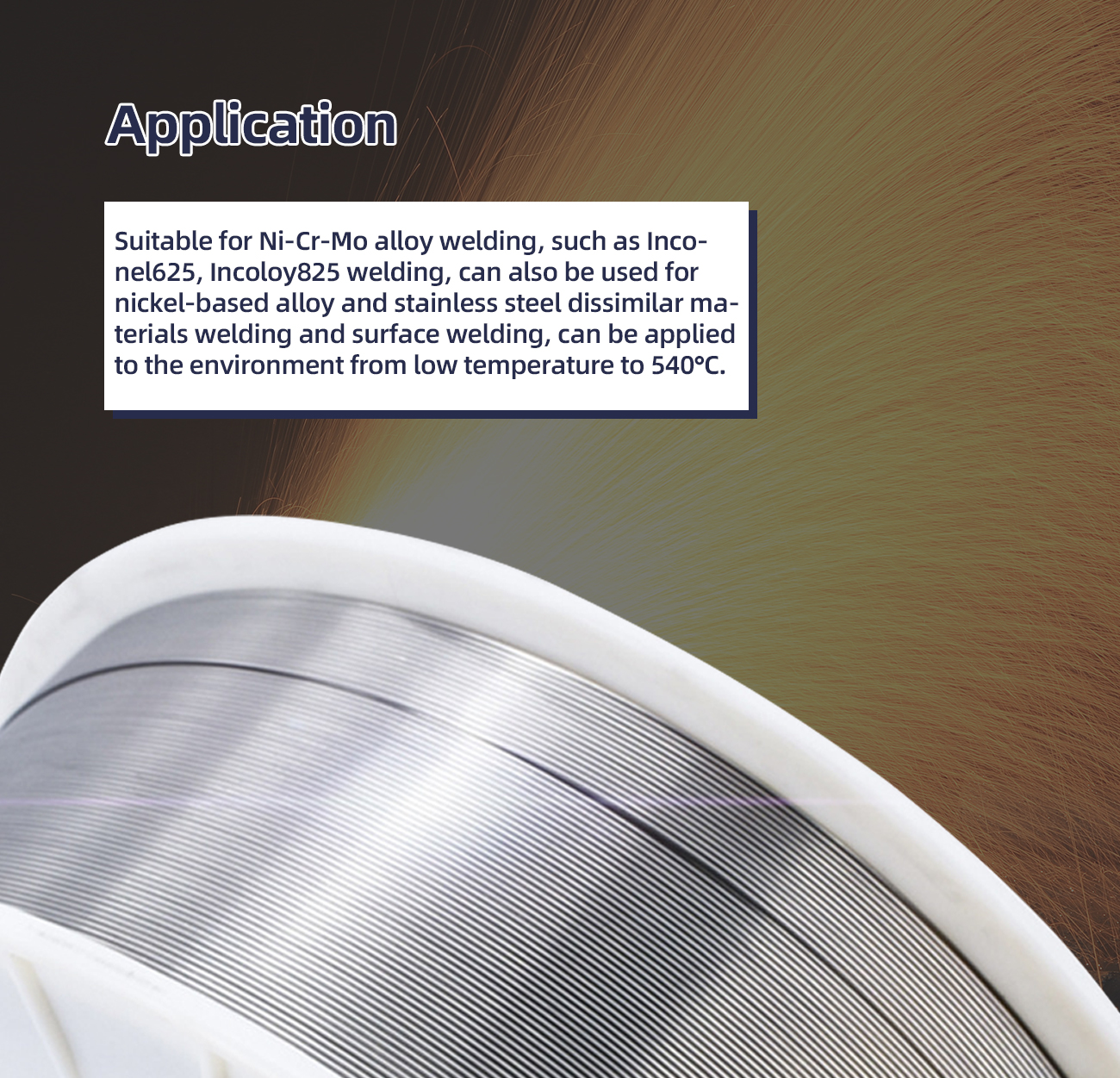

Nickel-chromium-molybdenum nickel-base alloy gas welding wire, nominal composition is 61%Ni-22%Cr-9%Mo-3.5%Nb+Ta.

Simbi yakanyungudutswa ine yakanaka mechanicha zvinhu uye kumira zvakanaka kugomba ngura uye kukoromoka.

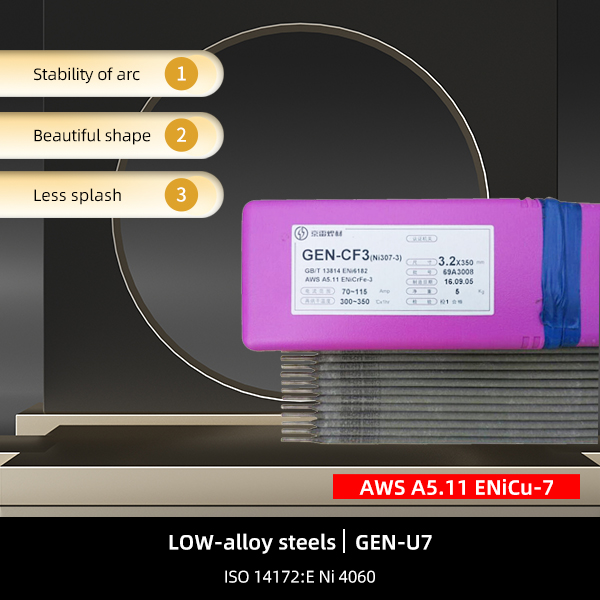

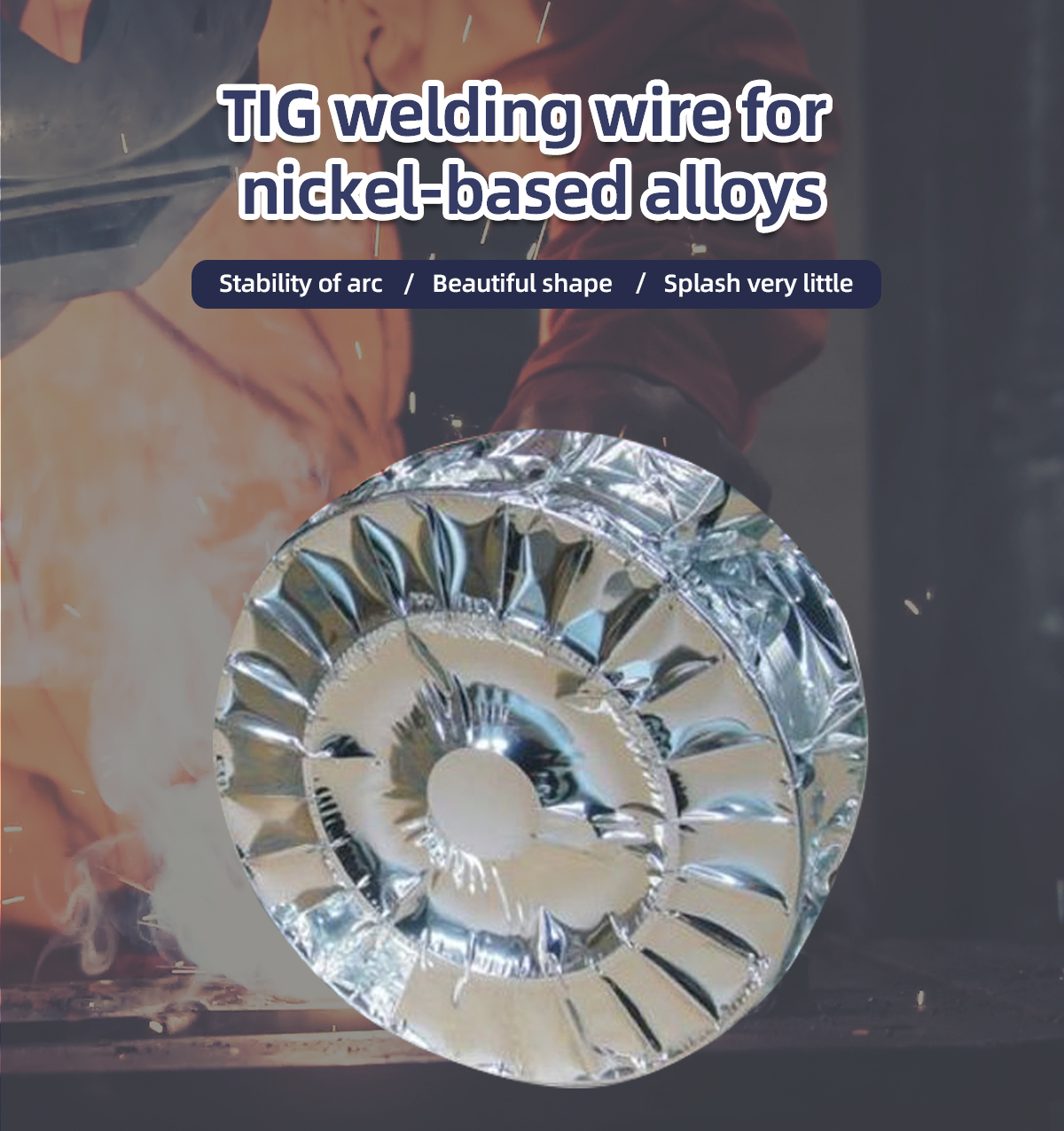

Yakagadzika arc, yakanaka kuumba, yakanaka kuyerera kwesimbi yakanyungudutswa, ine yakanakisa welding process performance.

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | Fe | Nb+Ta | P | S |

| GB/T RULES | 0.10 | 0.50 | 0.50 | 20.0-23.0 | ≥58 | 8.0-10.0 | 5.0 | 3.0-4.2 | - | - |

| AWS Mitemo | 0.10 | 0.50 | 0.50 | 20.0-23.0 | ≥58 | 8.0-10.0 | 5.0 | 3.15-4.15 | 0.02 | 0.015 |

| MUENZANISO VALUE | 0.006 | 0.15 | 0.12 | 22.02 | 64.84 | 8.75 | 0.18 | 3.49 | 0.001 | 0.001 |

MECHANICAL PROPERTY:

| PROPERTY | KUNYANYA SIMBA(MPa) | KUWEDZERA SIMBA(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | ||||

| GB/T RULES | - | - | - | - | ||||

| AWS Mitemo | - | - | - | - | ||||

| MUENZANISO VALUE | - | 790 | 159/-196 | 46 | ||||

Nyora meseji yako pano ugotitumira