Nickel alloys TIG ERNiCrFe-7A Soldering jointing

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | Fe | Nb+Ta | P | S |

| GB/T RULES | - | - | - | - | - | - | - | - | - | - |

| AWS Mitemo | 0.04 | 1.00 | 0.50 | 28.0-31.5 | Rem | 0.50 | 7.0-11.0 | 0.5-1.0 | 0.02 | 0.015 |

| MUENZANISO VALUE | 0.028 | 0.15 | 0.11 | 29.8 | 59.03 | 0.06 | 9.8 | 0.86 | 0.001 | 0.002 |

MECHANICAL PROPERTY:

| PROPERTY | KUNYANYA SIMBA(MPa) | KUWEDZERA SIMBA(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | Kurapa kwekupisa | ||||||

| GB/T RULES | - | - | - | - | - | ||||||

| AWS Mitemo | - | - | - | - | - | ||||||

| MUENZANISO VALUE | - | 760 | 133 / Tembiricha yekamuri | 37 | 607°C*25h | ||||||

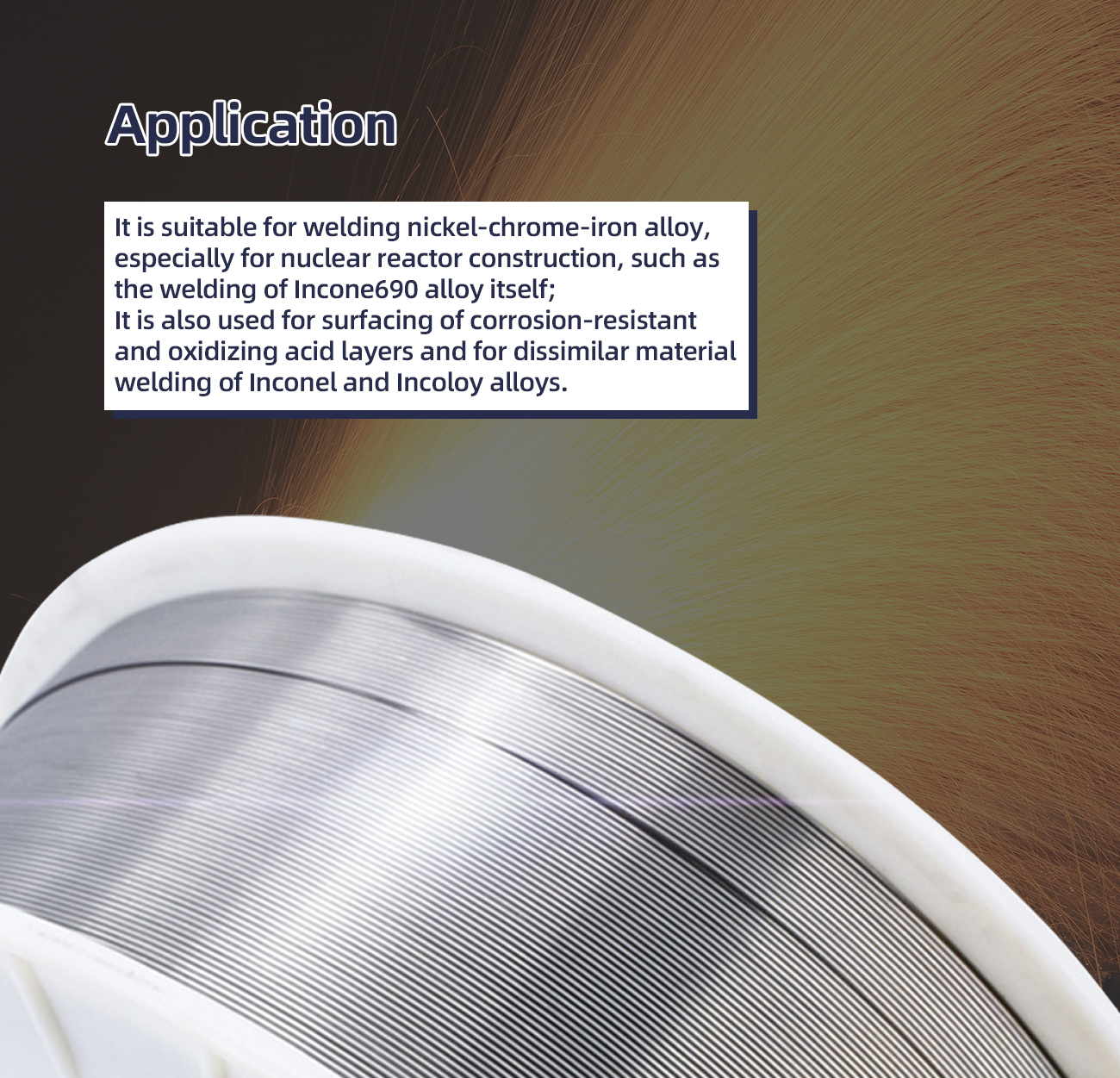

Nickel-chromium-iron nickel-base alloy gas welding wire, nominal composition is 60%Ni-29%Cr-9%Fe-0.75%Nb.

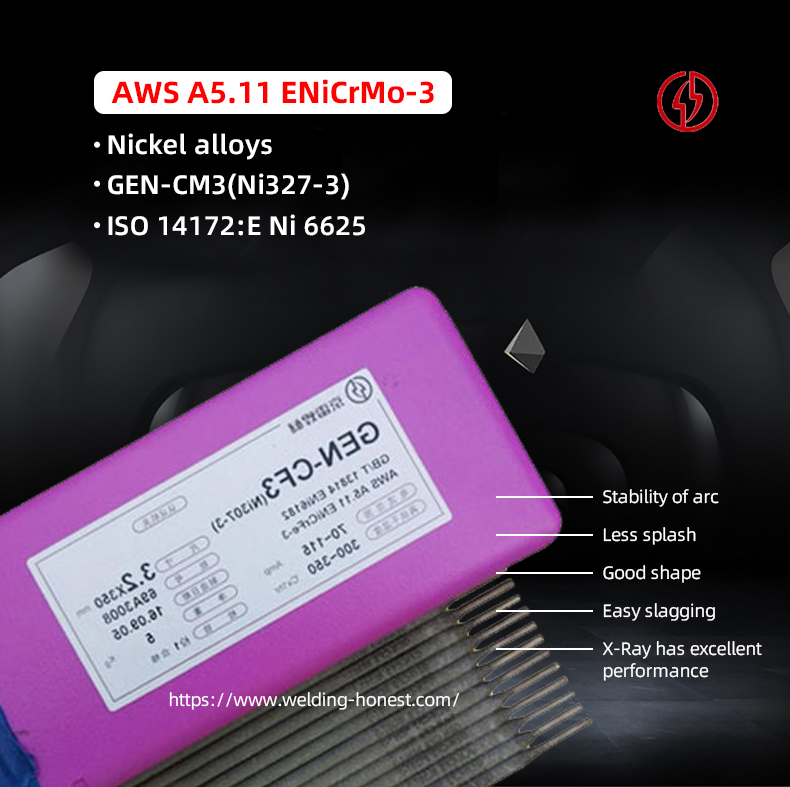

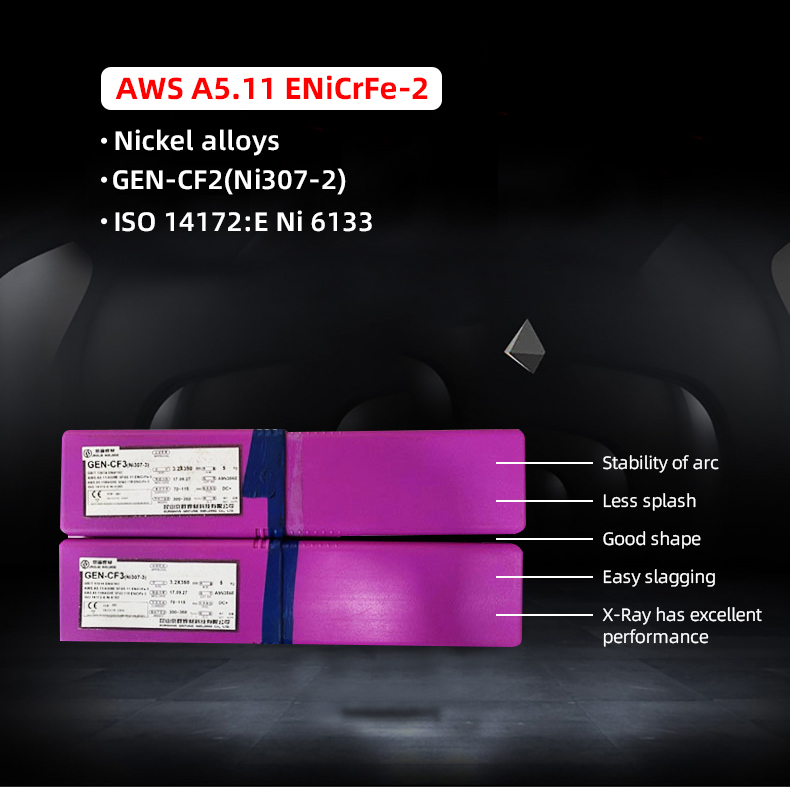

Yakanaka michina zvimiro zvesimbi yakanyungudutswa, kunyanya kuramba kudzika kwepurasitiki kupwanya (DDC).

Yakakwira Cr yemukati inoita kuti ive yakanakisa kusagadzikana corrosion kupaza kuramba munzvimbo yakachena yemvura pasi pemwaranzi mamiriro. Yakagadzika arc, yakanaka kuumba, yakanaka kuyerera kwesimbi yakanyungudutswa, ine yakanakisa welding process performance.

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | Fe | Nb+Ta | P | S |

| GB/T RULES | - | - | - | - | - | - | - | - | - | - |

| AWS Mitemo | 0.04 | 1.00 | 0.50 | 28.0-31.5 | Rem | 0.50 | 7.0-11.0 | 0.5-1.0 | 0.02 | 0.015 |

| MUENZANISO VALUE | 0.028 | 0.15 | 0.11 | 29.8 | 59.03 | 0.06 | 9.8 | 0.86 | 0.001 | 0.002 |

MECHANICAL PROPERTY:

| PROPERTY | KUNYANYA SIMBA(MPa) | KUWEDZERA SIMBA(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | Kurapa kwekupisa | ||||||

| GB/T RULES | - | - | - | - | - | ||||||

| AWS Mitemo | - | - | - | - | - | ||||||

| MUENZANISO VALUE | - | 760 | 133 / Tembiricha yekamuri | 37 | 607°C*25h | ||||||

Nyora meseji yako pano ugotitumira