Shongwe inoshandiswa kuita distillation, kucheneswa, kunyudza, distillation uye mamwe makemikari emidziyo, mazhinji eshongwe maturusi anofanirwa kubata acid, alkali, munyu, organic solvents uye imwe corrosive media, saka zvinodikanwa kuti utarise nzvimbo yakakura yecorrosion resistant layer. muhumburumbira uye zvikamu zvekuisa chisimbiso. Senzira inoshanda yekutarisa, strip sufacing inoshandiswa zvakanyanya mushongwe welding yemakemikari michina.

Iyo yechinyakare electrode sufacing tekinoroji ndeye kaviri-layer yakanyudzwa arc yakatarisana tekinoroji ine shanduko layer uye corrosion resistant layer, asi tekinoroji iyi ine nguva yakareba yekugadzira uye mutengo wakakwira wekugadzira. Kuti igadzirise dambudziko iri, JingQunCo yakagadzira-single-layer surfacing welding materials (GDS-309LA welding strip, GXS-ED308L electroslag flux), iyo inokwanisa kuzadzisa mhedzisiro ye-two-layer kutariswa nekungomira-layer pamusoro, uye inogona kurerutsa. iyo yekumusoro maitiro kubva kune maviri-layer kumusoro kune imwe-layer kumusoro.

Nhanganyaya ye welding materials

1.The Chemical chikamu

| Rules/Zita | C | Si | Mn | P | S | Cr | Ni | Note |

| NB/T47018.5 EQ309LA | ≤0.030 | ≤1.00 | 0.5-2.5 | ≤0.025 | ≤0.015 | 21.0-23.0 | 9.0-12.0 | solder strip |

| GDS-309LA | 0.018 | 0.34 | 1.90 | 0.017 | 0.001 | 21.96 | 11.17 | solder strip |

| Rules/Zita | NB/T47018.5 FZ308-D | GDS-309LA+GXS-ED308L solder strip + Flux musanganiswa | |||

| C | ≤0.05 | 0.028 | 0.028 | 0.029 | 0.029 |

| Si | ≤1.00 | 0.58 | 0.64 | 0.62 | 0.64 |

| Mn | ≤2.5 | 1.33 | 1.33 | 1.35 | 1.33 |

| P | ≤0.030 | 0.018 | 0.018 | 0.018 | 0.017 |

| S | ≤0.020 | 0.004 | 0.004 | 0.004 | 0.004 |

| Cr | 18.0-21.0 | 18.21 | 18.47 | 18.39 | 18.28 |

| Ni | 8.0-11.0 | 10.12 | 10.31 | 10.27 | 10.30 |

| Cherechedza | yakaiswa simbi | Welding pamusoro | Pasi pepamusoro 1mm | Pasi pepamusoro 2mm | Pasi pepamusoro 3mm |

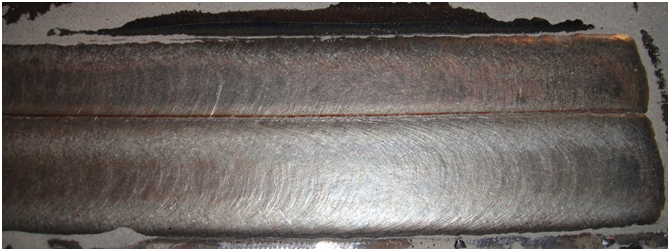

2.Weld kuonekwa

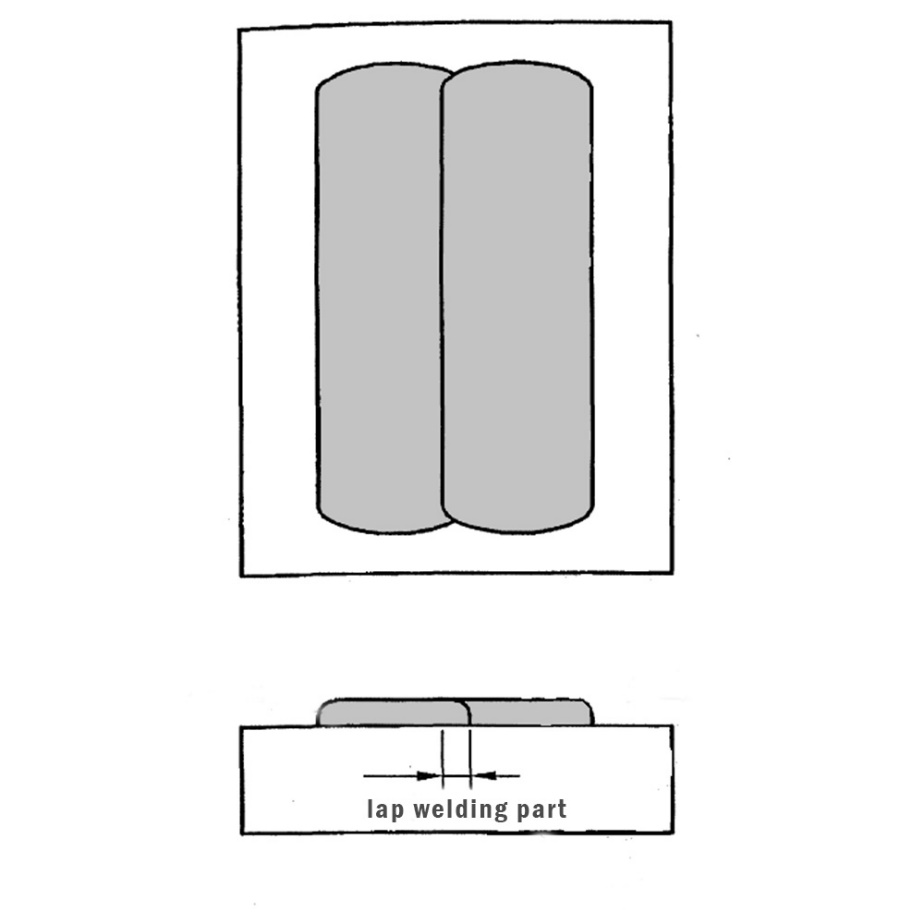

Yakakurudzirwa welding parameters

| Tsanangudzo(mm) | 0.5*60 |

| Magetsi(A) | 850-950 |

| Voltage(V) | 26-30 |

| Welding Speed(mm/min) | 150 |

| Length(mm) | 35-40 |

| Lap welding (mm/min) | 6-10 |

| Hukobvu hwekuyerera kupararira (mm/min) | Akusvika 25 |

Weld pass ukobvu: anenge 4.7mm

Weld hupamhi: anenge 62.5mm

Weld pass chitarisiko: yakanaka chimiro, weld surface iri flat, lap shanduko yakatsetseka.

3.Mechanical kugona

Ferrite yemukati (welded state)

| Solder strip + Flux musanganiswa | GDS-309LA+GXS-ED308L |

| Kuyerwa kukosha | Iyo ferrite yemukati inenge 7FN, uye iyo ferrite muzana yemukati inenge 8% |

| Kuyera nzvimbo | Weld pamusoro |

Muedzo nzira: GB/T 1954-2008 "chromium-nickel austenitic Stainless simbi weld ferrite zvemukati kuyerwa nzira"

Bending test:

as

620℃*20h

Miedzo mhinduro: lateral kupeta, indenter dhayamita 4T (40mm), kukotama Angle 180 ° pasina kutsemuka.

Intergranular corrosion test

Sezvo welded

620℃*20h

Nzira yekuedza: GB/T 4334-2020 Nzira E

Test mhinduro: mhangura - mhangura sulfate -16% sulfuric acid

Miedzo mhinduro: Hapana intergranular corrosion crack

Micro metallography yesurfacing layer

Sezvo welded

Sezvo welded

620 ℃ * 20h kupisa kurapwa

620 ℃ * 20h kupisa kurapwa

Injiniya application

1.Customer welding process evaluation process

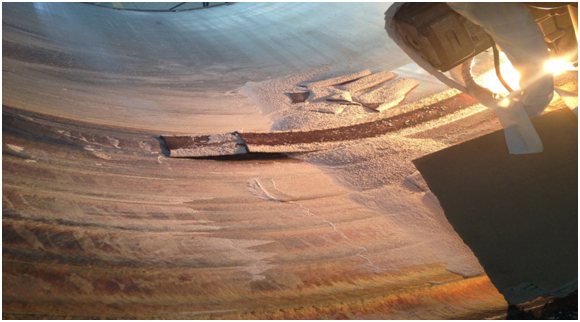

2.Customer site kuvaka

Mushure memakore ekutsvagisa nekusimudzira, Jingqun single-layer electroslag iri pamusoro welding material performance yakagadzikana uye yakavimbika, ine akawanda einjiniya application kubudirira.

Kugamuchirwa vatengi kubvunza uye kusarudza!

Ruzivo rwakawanda wedzera whatsapp+86 13252436578

E-Mail:sale@welding-honest.com

Nguva yekutumira: Nov-04-2022