Muna 2010, South Korea's POSCO, Daewoo Shipbuilding uye masangano mashanu makuru epasirese akatanga chirongwa che "kubatana kwekusimudzira simbi yakakwira manganese uye zvinhu zvewelding zvekupisa-yakaderera tembiricha", uye vakawana kugadzirwa kwakawanda kwesimbi yakakwira manganese kumatangi ekuchengetedza LNG. 2015. Pakazosvika Chikumi 2022, kupaza bhodhoro rehunyanzvi, South Korea's Daewoo Shipbuilding & Marine Engineering (DSME) uye POSCO ichaita yekutanga pasirese yekuisa yakakwirira-manganese simbi LNG mafuta ekuchengetedza matangi paLNG-inogonesa hombe crude carriers. (VLCCs) Mhemberero, uye yakataura kuti yakagadzira tekinoroji yekugadzira matangi emafuta kubva pakugadzirisa simbi kusvika kune welding nekugadzira.

1. Chii chakakwirira manganese simbi?

Yakakwira manganese simbi yeLNG matangi ekuchengetera isimbi yealloy ine manganese zviri pakati pe22-25%, ine yakanaka yakadzika tembiricha kuramba uye yakakwirira kupfeka kuramba, izvo zviri pachena kupfuura zvechinyakare LNG yekuchengetedza tangi zvinhu Ndiyo mudiwa mutsva weLNG yekuchengetedza tank zvinhu izvo South Korea yakapa mukutsvaga nekusimudzira kweanopfuura makore gumi.

2.Kuongorora kupfupi kwemhando dzesimbi uye zvakanakira nekuipira matangi ekuchengetedza LNG Yedu inofananidzwa welding consumables inogona kuzadzisa izvi zvakaomesesa zvinodiwa: Sezvo yakakura LNG mafuta ekuchengetedza matangi ndiyo yakakosha midziyo yezvakatipoteredza inoshamwaridzana nemafuta-powered ngarava uye iyo yese LNG industry chain, maitiro ehunyanzvi akanyanya kuomarara uye mutengo unodhura. LNG inowanzochengetwa uye kutakurwa pasi peyakanyanya-yakaderera tembiricha ye -163°C. Iyo "International Code yeKuvaka uye Equipment yeNgarava Dzinotakura Liquefied Gasi muBulk" inonzi "IGC Code". Zvinhu zvina zvakaderera-tembiricha zvinogona kushandiswa pakuvaka LNG zvinosanganisira: aluminium alloy simbi, Austria Tensitic Stainless simbi, austenitic Fe-Ni alloy simbi (inozivikanwawo seInvar simbi) uye 9% Ni simbi (ona Tafura 1 kuti uwane ruzivo). nepo 9% Ni simbi ndiyo inonyanya kushandiswa uye inoshandiswa zvakanyanya kuLNG mafuta ekuchengetera matangi. Asi zvipingamupinyi ndezvekuti mutengo uchiri wakakwira, maitiro ekugadzirisa anorema, simba rakaderera, uye nickel yemukati mune chigadzirwa yakakwira. Mumakore achangopfuura, nickel mutengo wakaramba uchikwira, uye mutengo wechigadzirwa wakawedzera zvakanyanya.

4 cryogenic zvinhu zvinogona kushandiswa muLNG kuvaka pasi pe "IGC Code"

| Minimum design tembiricha | Main simbi mhando uye kupisa kurapwa | Impact test tembiricha |

| -165 ℃ | 9% Ni simbi NNT kana QT | -196 ℃ |

| austenitic Stainless simbi - 304, 304L, 316/316L, 321 uye 347 mhinduro yakarapwa. | -196 ℃ | |

| Aluminium alloy - 5083 annealed | NO | |

| austenitic iron-nickel alloy (36%Ni) |

Kuenzanisa kwesimba pakati pezvinowanzoshandiswa LNG zvinhu uye itsva yakakwirira manganese simbi

| Item | Kazhinji alloy | high manganese simbi | ||||

| 9% Isimbi | 304 SS | Alu 5083-O | Invar simbi | MC | ||

| Base zvinhu | Kuumbwa Kwemakemikari | Fe-9Ni | Fe-18.5Cr-9.25Ni | Al-4.5Mg | Fe-36Ni | M CH mn |

| Microstructure | α1 (+Y) | γ(FCC) | FCC | FCC | FCC | |

| Goho SimbaMpa | ≥585 | ≥205 | 124-200 | 230-350 | ≥400 | |

| Tensile Simba Mpa | 690-825 | ≥515 | 276-352 | 400-500 | 800-970 | |

| -196 ℃ImpactJ | ≥41 | ≥41 | NO | NO | ≥41 | |

| Weldments | welding zvinodyiwa | Inconal | Type308 | ER5356 | - | FCA,SA,GTA |

| Goho SimbaMpa | - | - | - | - | ≥400 | |

| Tensile SimbaMpa | ≥690 | ≥550 | - | - | ≥660 | |

| -196 ℃ImpactJ | ≥27 | ≥27 | - | - | 27 | |

Ultra-yakaderera tembiricha yakakwira-manganese simbi, iyo inosanganisa kusimba kwakakwira, kusimba kwakanyanya, uye mutengo wakaderera, ine tarisiro yakafara kwazvo yekushandisa mune ramangwana LNG mafuta ekuchengetedza tangi uye kuchengetedzwa kwezvakatipoteredza imwe misika yemafuta ekuchengetedza matangi senge liquid ammonia, liquid hydrogen, uye methanol.

Kuumbwa uye kuita zvinodiwa zvesimbi yakakwira manganese

Kemikari Inoumbwa (ASTM Draft)

|

| C | Mn | p | s | Cr | Cu |

| % | 0.35-0.55 | 22.5-25.5 | <0.03 | <0.01 | 3.0-4.0 | 0.3-0.7 |

Mechanical maitiro

● Chimiro cheCrystal: face centered cubic lattice (γ-Fe)

● Tembiricha inobvumirwa>-196℃

● Goho simba>400MPa (58ksi)

● Kusimba kwesimba: 800~970MPa (116-141ksi)

● Charpy V-notch impact test >41J at -196℃(-320℉)

Kuunzwa kwekambani yedu yakakwira manganese simbi inoenderana newelding zvinodyiwa

Mumakore achangopfuura, takazvipira pachedu mukutsvagisa nekuvandudza kwepamusoro-manganese simbi inoenderana newelding zvinobatika zveLNG matangi ekuchengetera, uye nekubudirira kugadzirwa kwewelding consumables izvo zvinogona kuenderana zvivakwa zve-high-manganese simbi base zvinhu zveLNG matangi ekuchengetedza. Izvo chaizvo zvivakwa zvinoratidzwa muTafura 2.

Mechanical properties ye high manganese simbi inoenderana newelding consumables yakaiswa simbi

| Zita | Position | mechanical properties | ||||

| YP | TS | EL | -196 ℃ kukanganisa | radiographic bvunzo | ||

| Zvinangwa zvekugadzira | ≥400 | ≥660 | ≥25 | ≥41 | I | |

| GER-HMA Φ3.2mm | Manual electrode | 488 | 686 | 46.0 | 73.3 | I |

| GCR-HMA-S Φ3.2mm | Metal cored wire | 486 | 700 | 44.5 | 62.0 | I |

Ps.Metal powder core yakanyura arc welding wire ye high manganese simbi inotora matching flux GXR-200 ye high manganese simbi.

Weldability uye sampuli kuratidzwa kweakakwira manganese simbi welding zvinodyiwa zveLNG matangi ekuchengetedza

Iyo weldability yewelding zvinodyiwa zvepamusoro manganese simbi inoratidzwa sezvinotevera

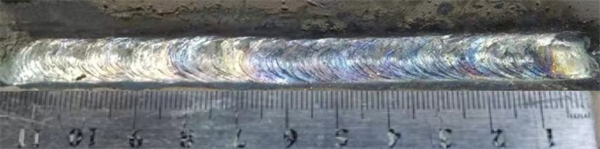

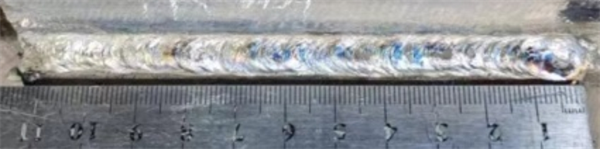

Electrode (GER-HMA) flat fillet welding mushure mekubviswa slag

Electrode (GER-HMA) elevation angle welding mushure mekubvisa slag

Welding tsvimbo (GER-HMA) pamberi uye pashure fillet welding slag kubviswa

Metal poda yepakati yakanyura arc (GCR-HMA-S) weld kuratidza

Iwo masampula epamusoro manganese simbi welding tsvimbo welding majoini anoratidzwa sezvinotevera

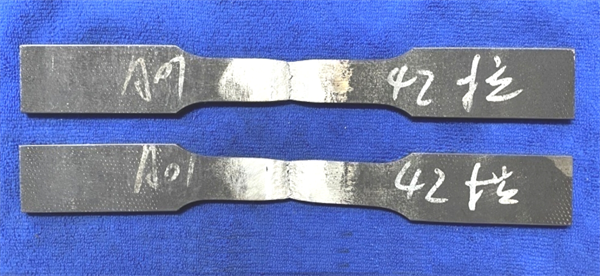

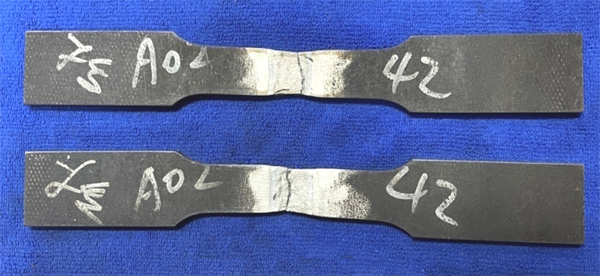

Flat welding (1G) tensile sampuli kuratidza

Vertical welding (3G) tensile sampuli kuratidza

Flat welding (1G) kubhenda sampuli kuratidza

Flat welding (1G) kubhenda sampuli kuratidza

PS. Yakakwirira manganese simbi inosungirirwa netsvimbo yekushivirira 1G uye 3G, hapana kuputika kumeso kunokotama uye kumashure kubhenda samples, uye kuramba kutsemuka kwakanaka.

Nguva yekutumira: Nov-22-2022