Web: www.welding-honest.com +8613252736578

Pure aluminiyamu isimbi yakapfava uye inonyatso ductive. Kune dzakawanda zvivako, simba rayo rakaderera. Kuti uwedzere kusimba kwealuminium, alloying zvinhu zvinoda kuwedzerwa. Mhangura, silicon, manganese, magnesium, uye zingi zvinoshandiswa sechinhu chikuru kutamba yakasimba -soluble reinforcement effect. Aluminium nealuminium alloy zvakashandiswa zvakanyanya mumaindasitiri mazhinji.

Iyo welding yealuminium nealuminium alloy yakaoma kupfuura yakaderera -carbon simbi. Hunhu hwayo hwekutungirira hwakasiyana kubva kune yakaderera-kabhoni simbi. Iyo chaiyo performance ndeyekutevera:

1. Soferality ye welded inobatanidza mechanical performance, yakaderera corrosion resistance.

2. Basa remakemikari rakasimba kwazvo, uye nzvimbo yacho inoumbwa nyore nyore.

3. Yakasimba thermal conductivity, uye zviri nyore kukonzera insoluble phenomenon panguva welding.

4. Kuremara kwakabudirira senge pores, kuputika, bite edges, slag uye weld kugadzira.

5. Mutsara wakakura wekuwedzera coefficient (inenge 2 nguva yakaderera-carbon simbi), iyo inotarisana nehondo uye deformation panguva yekuputika.

6. Thermal conductivity yakakura (inenge 5 times the low-carbon steel). Pakumhanya kwakafanana kwewelding, thermal input inosvika 2 kusvika 4 hombe pane welding simbi.

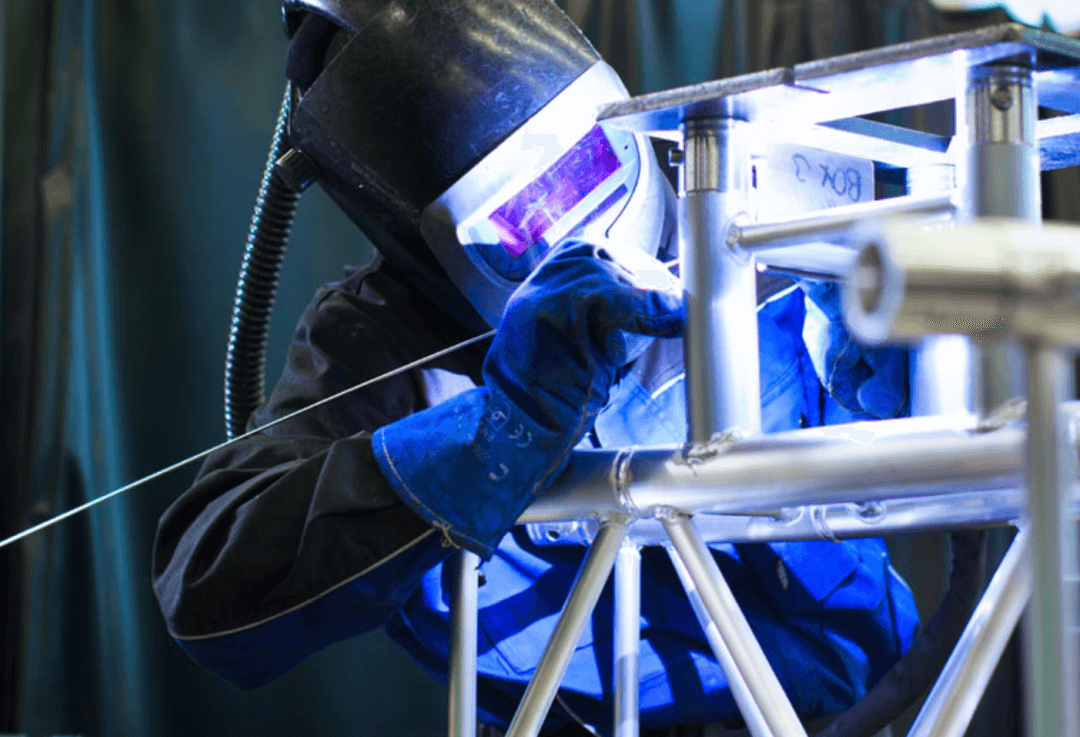

Iyo aluminium alloy yakasungwa neTIG kana GMAW.

1.Aluminium alloy tig welding

Kana iwe uchida kuwana yemhando yepamusoro welding, Tig welding inowanzova sarudzo yekutanga. Iyo yakanyanya kukodzera maitiro maitiro ndeyekuchinjana TIG welding uye AC pulse TIG welding. Pane zvakawanda zvakanakira:

1. Kana welding, iyo cathode atomization maitiro anogona kubviswa ega.

2. Iyo fomu yekubatanidza haina kuganhurirwa, iyo yepamusoro inotsvedza uye yakanaka yekuumba.

3. Nzvimbo yewelding yemhepo inoyerera kuti itonhodze majoini kuti itonhorere pasi uye kuvandudza sangano uye kushanda.

Naizvozvo, maitiro aya akanyatsokodzera mumhando yepamusoro-soro uye yakakosha zvakanyanya indasitiri yemuchadenga. Zvechokwadi, zvisingabatsiri zvayo zviri pachena zvakare. Welding inoshanda yakaderera, uye haina kukodzera kugadzirwa kwehombe-yepamusoro-inoshanda.

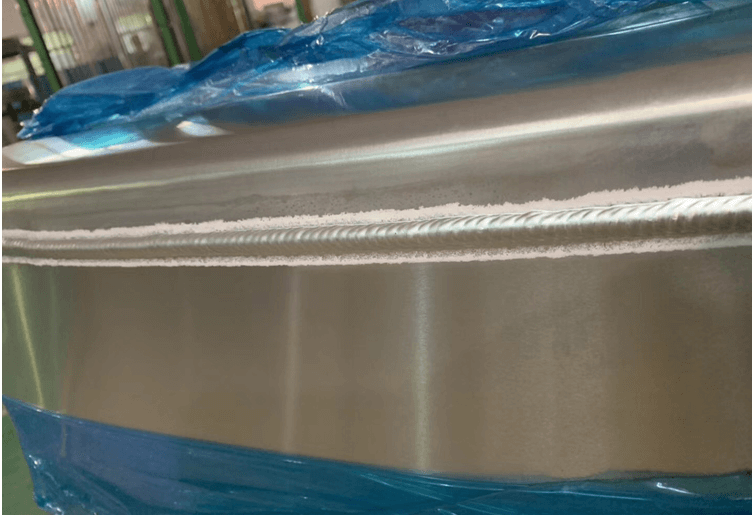

1.Aluminium alloy GMAW welding

Gmaw welding yakapinda muhupenyu hwedu zvishoma nezvishoma. DC reverse yekubatanidza inowanzo shandiswa panguva yekushongedza, uye pulse welding inogona kushandiswa zvakare. Kuenzaniswa neTIG welding, GMAW welding ine zvinotevera zvakanakira:

1. Iko kunenge kusina oxidative inopisa panguva yekugadzira, uye nzira yacho iri nyore.

2. Kuwanda kwekushanda kwebasa.

3. Usatora tungsten matanda, mutengo wakaderera.

Kana welding muGMAW, teerera kune zvinotevera pfungwa:

1. Iwe unoda kushandisa plastiki-based silk hose, uye simbi yesimbi haigoni kushandiswa.

2. Iyo aluminiyumu welding wire yakapfava uye waya yekutumira haina kunaka. Iwe unofanirwa kusarudza U-shaped groove wire delivery vhiri.

3. Shandisa zvakakodzera mukati dhayamita conductive muromo.

4. Usagovera zvikamu nesimbi welding kuti urege kusvibiswa.

GMA-A5356 inoshandisa mhedzisiro pane saiti yemutengi

Iyi data inogoverana nevashandisi vari kuenderera mberi kana kuti vave kuda kugadzirwa, zvichitibvumira kufambira mberi mumugwagwa wealuminium alloy welding.

Izvo zvakajairwa zvigadzirwa zvekambani yedu ndezvizvi:

TIG MIG

GTA-A4043 GMA-A4043

GTA-A5183 GMA-A5183

GTA-A5356 GMA-A5356

Nguva yekutumira: Nov-14-2022