Munguva yekuomesa maitiro, kutsemuka kunowanzo kukonzera matambudziko senge rework uye kudzoka kwevatengi. Yakaomeswa yakatarisana neyakajairwa dhizaini welding, uye kutonga uye kutarisisa nzira yekutsemuka kwakasiyanawo. Ichi chinyorwa chinoongorora uye chinokurukura chitarisiko chakajairwa chekutsemuka mukati mekuita kwe hardfacing wear-resistant surface.

1. Kutsunga kwekutsemuka

Parizvino, munyika uye kunyangwe pasirese, hapana mwero wakajairwa wekutsemuka kunokonzerwa nekuoma kwepasi. Chikonzero chikuru ndechekuti kune marudzi akawandisa emamiriro ekushanda ezvigadzirwa zvezvipfeko zvekupfeka zvakaoma, uye zvakaoma kutsanangura zvakasiyana-siyana Zvinoshanda zvekutonga kwecrack pasi pemamiriro ezvinhu. Nekudaro, maererano neruzivo mukushandiswa kwezvakaoma-zvakatarisana nekupfeka-zvinodzivirira welding zvinhu mundima dzakasiyana, akati wandei madhigirii ecrack anogona kurongeka zvine hukasha, pamwe nemaitiro ekugamuchirwa mumaindasitiri akasiyana:

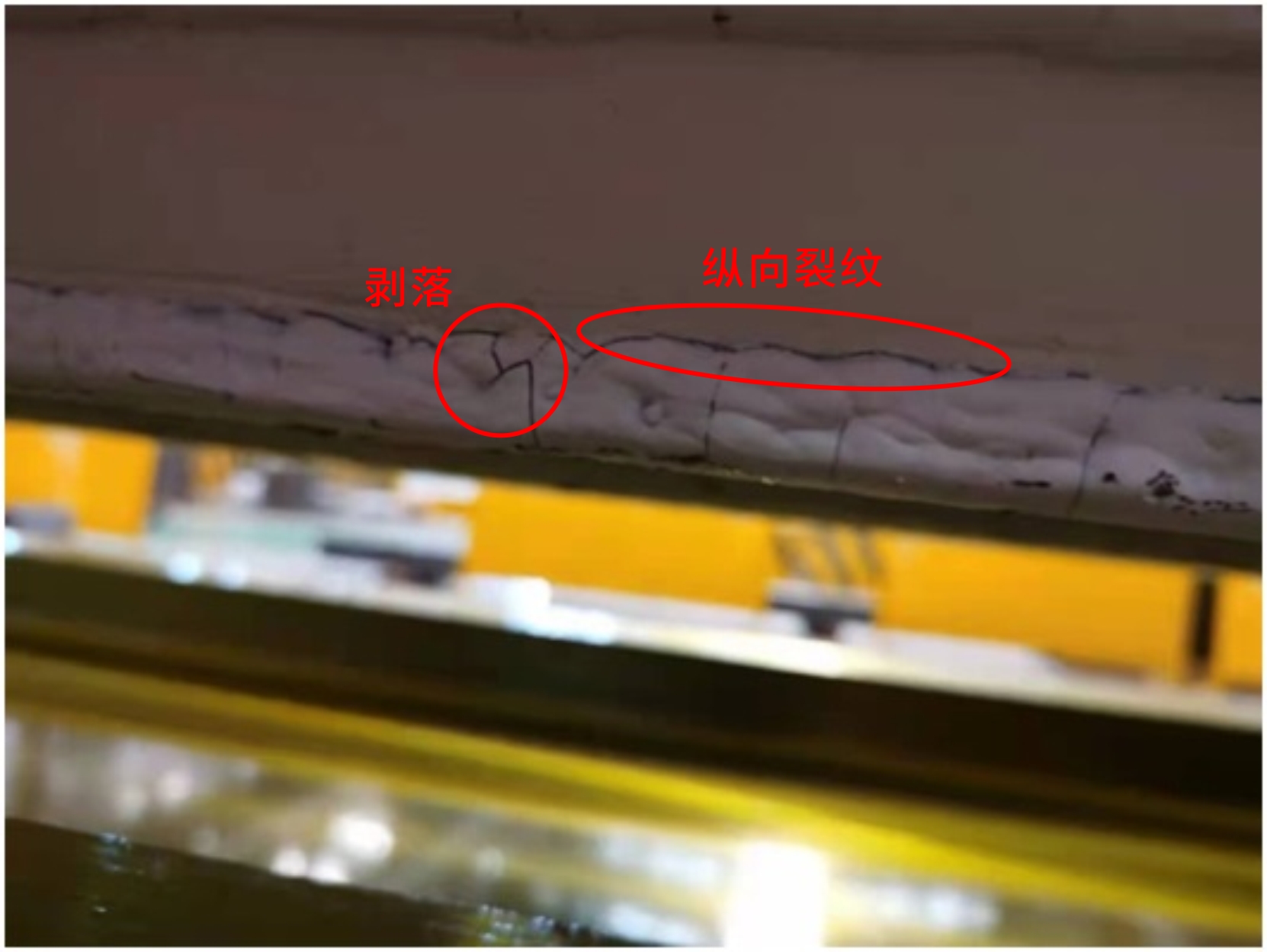

1. Nzvimbo yekutsemuka inofambirana ne bead ye weld (longitudinal crack), inoenderera ichitsemuka, mutswe uchienda ku base simbi, spalling.

Chero bedzi imwe yeaya ambotaurwa pamusoro peiyo crack level yasangana, pane njodzi yekuti iyo yese yekumusoro layer inodonha. Chaizvoizvo, zvisinei kuti chigadzirwa chekushandisa chii, hachigamuchirwe uye chinogona kungogadziriswa uye kutengeswa zvakare.

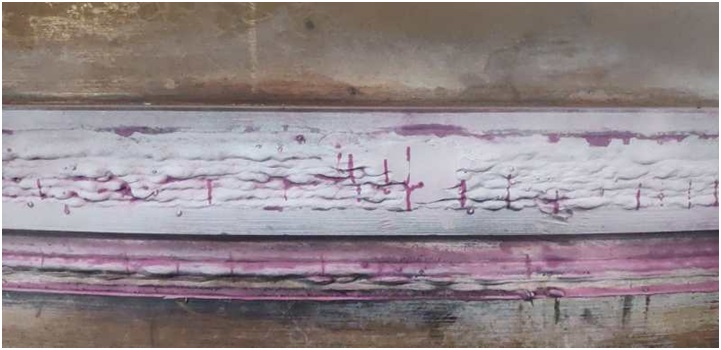

2. Pane chete mhiri makatsemuka uye discontinuity

Kune maworkpiece ari kusangana nezvinhu zvakasimba senge ore, sandstone, uye migodhi yemarasha, kuomarara kunodiwa kuve kwakakwira (HRC 60 kana kupfuura), uye yakakwirira-chromium welding zvinhu zvinowanzo shandiswa pakuisa welding. Iyo chromium carbide makristasi akaumbwa mu weld bead anozogadzirwa nekuda kwekushushikana kusunungurwa. Makatsemuka anogamuchirwa chero nzira yekutsemuka ingori perpendicular kune weld bead (yakachinjika) uye inomira. Nekudaro, iyo nhamba yekutsemuka ichiri kushandiswa sereferensi yekuenzanisa zvakanakira uye zvakaipira zvewelding zvinodyiwa kana maitiro epamusoro.

3. Hapana crack weld bead

Kune maworkpieces akadai semaflange, mavharuvhu, uye mapaipi, uko hombe yekubata zvinhu ari magasi uye zvinwiwa, zvinodikanwa zvekutsemuka mu weld bead zvakanyanya kuchenjerera, uye zvinowanzodiwa kuti chitarisiko che weld bead chisave nekutsemuka.

Kutsemuka kudiki pamusoro pezvishandiso zvakaita semaflange nemavharuvhu zvinoda kugadziriswa kana kugadzirwazve.

Shandisa yekambani yedu GFH-D507Mo vharafu yakakosha welding inoshandisika yekutarisa, hapana makatsemuka pamusoro.

2. Zvikonzero zvikuru zvekuoma kwepasi kupfeka-resistant surfacing cracks

Pane zvinhu zvakawanda zvinokonzera kutsemuka. Kune yakaoma pamusoro kupfeka-resistant surfacing welding, inogona kunyanya kupatsanurwa kuita kuputika kunopisa kunogona kuwanikwa mushure mekutanga kana kwechipiri kupasa, uye kutonhora kutsemuka kunoonekwa mushure mekupfuura kwechipiri kana kunyangwe mushure mese welding.

Hot crack:

Munguva yewelding process, simbi iri mu weld seam uye inopisa-yakakanganiswa zone inotonhorera kune yakakwirira-tembiricha zone padyo neiyo solidus mutsetse kuti ibudise makatsemuka.

Cold crack:

Kutsemuka kunogadzirwa pakupisa kuri pasi peiyo solidus (inenge paiyo martensitic shanduko tembiricha yesimbi) inonyanya kuitika mumasimbi epakati-kabhoni uye yakakwirira-yakasimba yakaderera-alloy simbi uye yepakati-alloy simbi.

Sezvinoratidzwa nezita racho, zvigadzirwa zvepasi zvakaoma zvinozivikanwa nekuoma kwazvo kwepamusoro. Nekudaro, kutsvaga kwekuoma mumakanika kunoguma nekudzikira kwepurasitiki, ndiko kuti, kuwedzera kwebrittleness. Kazhinji kutaura, kutarisisa pamusoro peHRC60 hakutarise zvakanyanya kune makatsemuka ekupisa anogadzirwa panguva yewelding process. Nekudaro, yakaoma pamusoro pekuisa welding nekuoma pakati peHRC40-60, kana paine chinodiwa chekutsemuka, Iyo intergranular mitswe muwelding process kana liquefaction uye multilateral makatsemuka anokonzerwa nepamusoro weld bead kune inopisa-inokanganisa nzvimbo yezasi weld. bead dzinonetsa zvikuru.

Kunyangwe kana dambudziko rekutsemuka rinopisa richidzorwa zvakanaka, kutyisidzira kwekutsemuka kunotonhora kuchiri kutarisana mushure mekuisa welding, kunyanya iyo yakanyanya brittle zvinhu senge hard surface weld bead, iyo inonyanya kunzwisiswa nechando. Kutsemuka kwakanyanya kunonyanya kukonzerwa nekutsemuka kunotonhora

3. Zvinhu zvakakosha zvinokanganisa kuputika-kusagadzikana kwakatsemuka panzvimbo dzakaoma uye mazano ekudzivirira kuputika

Zvinhu zvakakosha zvinogona kuongororwa kana kuputika kukaitika mukuoma kwepamusoro kupfeka maitiro ndeaya anotevera, uye nzira dzinoenderana dzinotsanangurwa kune chimwe nechimwe chinhu kuderedza njodzi yekutsemuka:

1. Base zvinhu

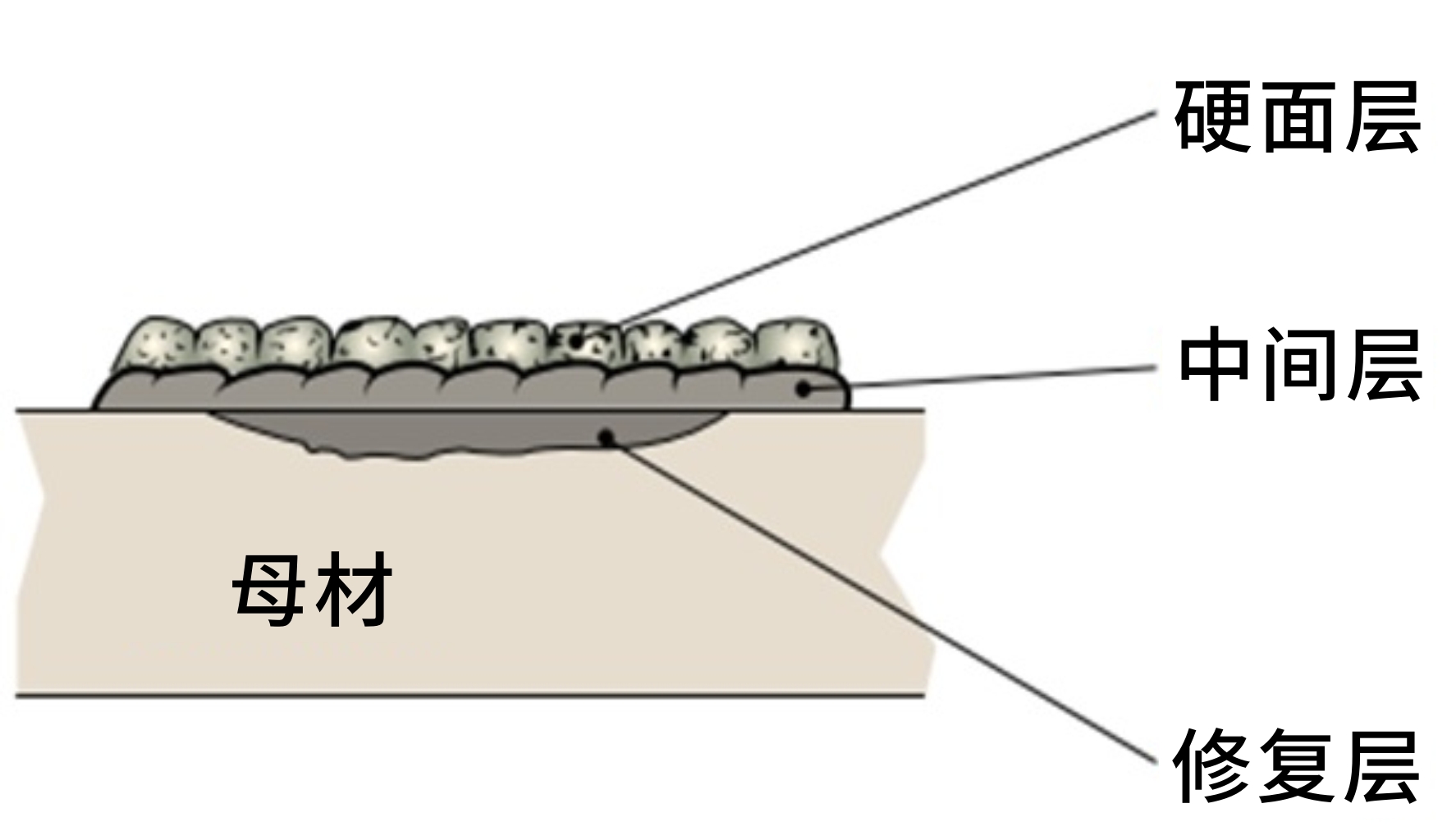

Kufurira kwe base simbi pane yakaoma pamusoro kupfeka-inodzivirira pamusoro pepamusoro kwakakosha zvakanyanya, kunyanya kune maworkpiece ane asingasviki maviri akaturikidzana epamusoro welding. Kuumbwa kwesimbi yepasi kunobata zvakananga zvinhu zve weld bead. Kusarudzwa kwezvinhu inyaya inoda kutariswa isati yatanga basa. Semuyenzaniso, kana vharafu yekushanda ine chinangwa chekuoma kweHRC30 ichitarisana nesimbi yakagadzirwa nesimbi, zvinokurudzirwa kushandisa welding zvinhu zvine kuoma zvishoma, kana kuwedzera chidimbu chesimbi isina tsvina yepakati, kuitira kuti dzivirira iyo kabhoni yemukati mune base zvinhu kubva pakuwedzera njodzi yekutsemuka kwe weld bead.

Wedzera yepakati layer pane base zvinhu kuti uderedze njodzi yekutsemuka

2. Welding consumables

Kune iyo nzira iyo isingade kutsemuka, yakakwirira-kabhoni uye yakakwirira-chromium welding zvinodyiwa hazvina kukodzera. Inokurudzirwa kushandisa martensitic system welding consumables, senge yedu GFH-58. Inogona kupinza bhiza risina kutsemuka kana kuoma kwacho kwakakwira seHRC58~60, kunyanya yakanakira nzvimbo dzisina kurongeka dzebasa dzinokwenya zvakanyanya nevhu nematombo.

3. Kuisa kupisa

Kuvakwa kwepa-saiti kunowanzo shandisa yakakwira ikozvino uye voltage nekuda kwekusimbisa kwekushanda, asi zvine mwero kuderedza ikozvino uye voltage kunogonawo kudzikisa zvinobudirira kuitika kwekutsemuka kwekupisa.

4. Kudzora tembiricha

Multi-layer uye multi-pass hardfacing welding inogona kutorwa senzira yekuenderera mberi kudziyisa, kutonhora uye kudzoreredza kune imwe neimwe pass, saka tembiricha yekudzora yakakosha, kubva pakupisa kusati kwave nemoto welding kuti upfuure tembiricha panguva yekudzora kwepamusoro, uye kunyangwe kutonhora mushure. welding, inoda kutariswa kukuru.

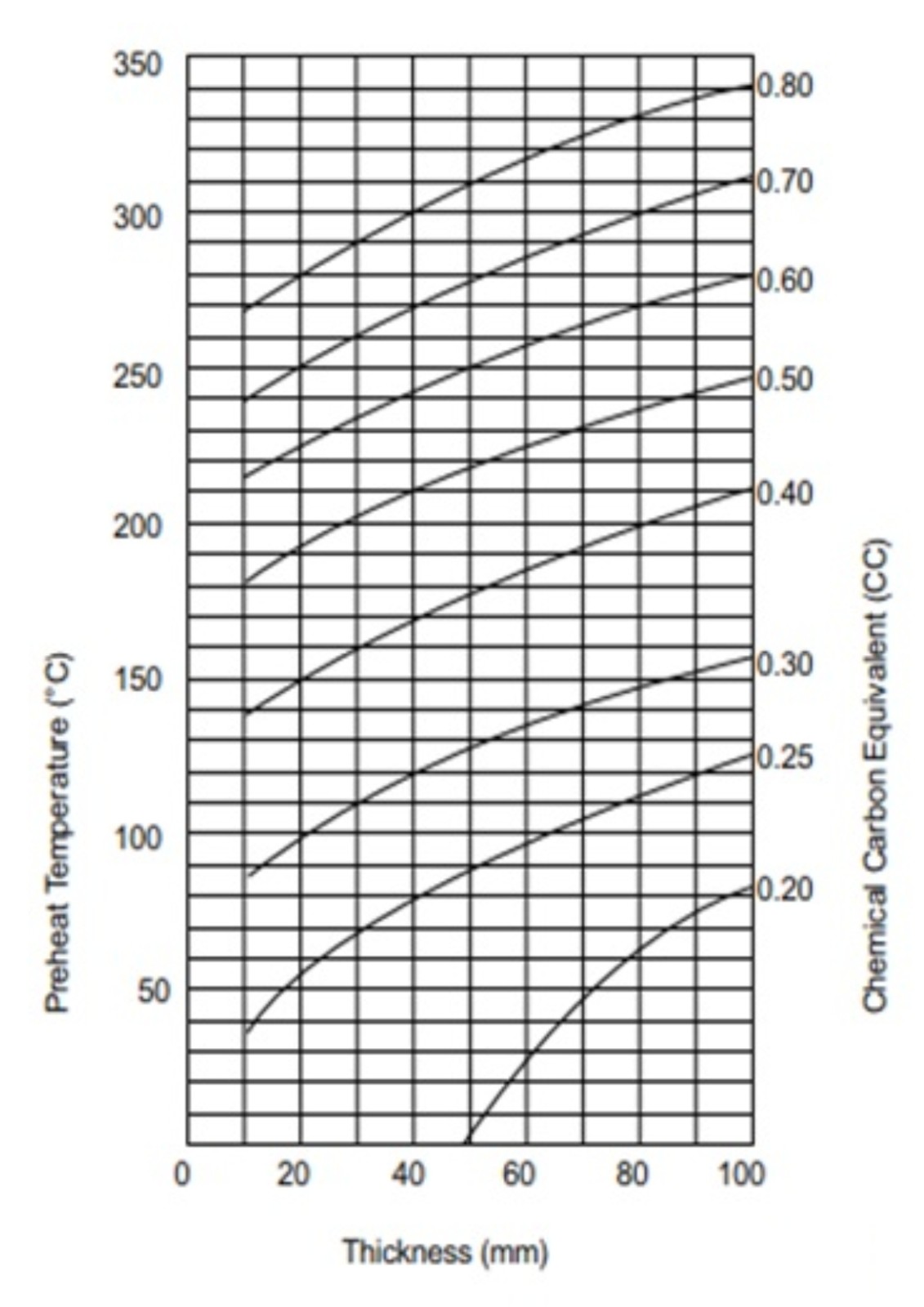

Iyo preheating uye yekutevera tembiricha yekumusoro welding yakabatana zvakanyanya neiyo kabhoni yemukati meiyo substrate. Iyo substrate pano inosanganisira iyo yepasi zvinhu kana yepakati layer, uye pasi peiyo yakaoma nzvimbo. Kazhinji kutaura, nekuda kwekabhoni yemukati weiyo yakaoma nzvimbo yakaiswa simbi Kana zvirimo zvakakwirira, zvinokurudzirwa kuchengetedza tembiricha yemugwagwa pamusoro pe200 degrees. Nekudaro, mukushanda chaiko, nekuda kwehurefu hurefu hweiyo weld bead, chikamu chemberi che weld bead chakatonhodzwa nekupera kwechipfuura chimwe, uye chechipiri chinopfuura chinoburitsa nyore kuputika munzvimbo inobatwa nekupisa kwe substrate. . Naizvozvo, mukushaikwa kwemidziyo yakakodzera kuchengetedza tembiricha yechiteshi kana preheat isati yanyungudutswa, zvinokurudzirwa kushanda muzvikamu zvakawanda, mapfupi welds, uye kuenderera mberi kwekuisa welding muchikamu chimwe chete kuchengetedza tembiricha yechiteshi.

Hukama pakati pekabhoni yemukati uye preheating tembiricha

Iko kunonoka kutonhora mushure mekutarisa zvakare inhanho yakaoma asi inowanzoregeredzwa, kunyanya kune makuru maworkpiece. Dzimwe nguva hazvisi nyore kuve nemidziyo yakakodzera yekupa inononoka kutonhora mamiriro. Kana pasina chaizvo nzira yekugadzirisa mamiriro ezvinhu aya, tinogona kungokurudzira kuishandisa zvakare Nzira yekushanda kwezvikamu, kana kudzivisa kutarisana nevelding kana kutonhora kwakaderera, kuderedza dambudziko rekuputika kwechando.

Four. Mhedziso

Pachine misiyano mizhinji yevagadziri vega mune zvinodikanwa zvekuomesera kwekutsemuka mune zvinoshanda maapplication. Ichi chinyorwa chinongoita nhaurirano yakakasharara yakavakirwa paruzivo rushoma. Yedu yekambani yakaoma pamusoro pekupfeka-inodzivirira yakatevedzana yewelding consumables ine inoenderana zvigadzirwa zvevatengi kusarudza kune kwakasiyana kuomarara uye maapplication. Kugamuchirwa kubvunza nebhizinesi mudunhu rega rega.

Kushandiswa kwefekitari yebhodhi inopfeka-inodzivirira

| Item | Chengetedza gasi | saizi | Main | HRC | Kushandisa |

| GFH-61-0 | Kuzvidzivirira | 1.6 2.8 3.2 | C:5.0 Si:0.6 Mn:1.2 Cr:28.0 | 61 | Inokodzera kukuya mavhiri, simende mixers, bulldozers, nezvimwe. |

| GFH-65-0 | Kuzvidzivirira | 1.6 2.8 3.2 | C:5.0 Cr:22.5 Mo:3.2 V:1.1 W:1.3 Nb:3.5 | 65 | Inokodzera tembiricha yakakwira yekubvisa guruva fan blades, blast furnace yekudyisa michina, nezvimwe. |

| GFH-70-O | Kuzvidzivirira | 1.6 2.8 3.2 | C:5.0 Cr:30.0 B:0.3 | 68 | Inoshanda kune marasha roller, ghost red, kugamuchira giya, kuputika marasha chivharo, grinder, nezvimwe. |

Kushandiswa muindasitiri yesimende

| Item | Chengetedza gasi | saizi | Main | HRC | Kushandisa |

| GFH-61-0 | Kuzvidzivirira | 1.6 2.8 3.2 | C:5.0 Si:0.6 Mn:1.2 Cr:28.0 | 61 | Inokodzera kukuya matombo rollers, simende mixers, nezvimwe |

| GFH-65-0 | Kuzvidzivirira | 1.6 2.8 3.2 | C:5.0 Cr:22.5 Mo:3.2 V:1.1 W:1.3 Nb:3.5 | 65 | Inokodzera tembiricha yakakwira yekubvisa guruva fan blades, blast furnace yekudyisa michina, nezvimwe. |

| GFH-70-O | Kuzvidzivirira | 1.6 2.8 3.2 | C:5.0 Cr:30.0 B:0.3 | 68 | Inokodzera kukuya matombo rollers, ghost mazino, kugashira mazino, grinders, nezvimwe. |

| GFH-31-S | GXH-81 | 2.8 3.2 | C:0.12 Si:0.87 Mn:2.6 Mo:0.53 | 36 | Inoshanda kune simbi-kune-simbi kupfeka zvikamu zvakaita semavhiri ekorona uye maekisi |

| GFH-17-S | GXH-81 | 2.8 3.2 | C:0.09 Si:0.42 Mn:2.1 Cr:2.8 Mo:0.43 | 38 | Inoshanda kune simbi-kune-simbi kupfeka zvikamu zvakaita semavhiri ekorona uye maekisi |

Steel Plant Application

| Item | Chengetedza gasi | saizi | Main | HRC | Kushandisa |

| GFH-61-0 | Kuzvidzivirira | 1.6 2.8 3.2 | C:5.0 Si:0.6 Mn:1.2 Cr:28.0 | 61 | Inokodzera sintering chirimwa chevira mabara, mazino emweya, mahwendefa asingapfeke, nezvimwe. |

| GFH-65-0 | Kuzvidzivirira | 1.6 2.8 3.2 | C:5.0 Cr:22.5 Mo:3.2 V:1.1 W:1.368 Nb:3.5 | 65 | |

| GFH-70-0 | Kuzvidzivirira | 1.6 2.8 3.2 | C:5.0 Cr:30.0 B:0.3 | 68 | |

| GFH-420-S | GXH-81 | 2.8 3.2 | C:0.24 Si:0.65 Mn:1.1 Cr:13.2 | 52 | Inokodzera kukanda mipumburu, mipumburu yekufambisa, mitsetse yekufambisa, nezvimwewo muzvirimwa zvinoramba zvichikanda uye zvidyarwa zvinopisa. |

| GFH-423-S | GXH-82 | 2.8 3.2 | C:0.12 Si:0.42 Mn:1.1 Kr:13.4 Mo:1.1 V:0.16 Nb:0.15 | 45 | |

| GFH-12-S | GXH-81 | 2.8 3.2 | C:0.25 Si:0.45 Mn:2.0 Cr:5.8 Mo:0.8 V:0.3 W:0.6 | 51 | Anti-adhesive kupfeka zvivakwa, yakakodzera simbi ndiro fekitori dhiraivha, pinch rolls uye kupfeka zvikamu pakati pesimbi. |

| GFH-52-S | GXH-81 | 2.8 3.2 | C:0.36 Si:0.64 Mn:2.0 Ni:2.9 Cr:6.2 Mo:1.35 V:0.49 | 52 |

Miner Application

| Item | Chengetedza gasi | saizi | Main | HRC | Kushandisa |

| GFH-61-0 | Kuzvidzivirira | 1.6 2.8 3.2 | C:5.0 Si:0.6 Mn:1.2 Cr:28.0 | 61 | Inoshanda kune vanochera, misoro yemigwagwa, mapikicha, nezvimwe. |

| GFH-58 | CO2 | 1.6 2.4 | C:0.5 Si:0.5 M:0.95 Ni:0.03 Cr:5.8 Mo:0.6 | 58 | Inokodzera kukwirisa welding padivi pedombo rekutumira trough |

| GFH-45 | CO2 | 1.6 2.4 | C:2.2 Si:1.7 M:0.9 Cr:11.0 Mo:0.46 | 46 | Inokodzera kupfeka zvikamu pakati pesimbi |

Kushandisa valve

| Item | Chengetedza gasi | saizi | Main | HRC | Kushandisa |

| GFH-D507 | CO2 | 1.6 2.4 | C:0.12 S:0.45 Mn:0.4 Ni:0.1 Kr:13 Mo:0.01 | 40 | Inokodzera kusevha welding yevharuvhu sealing surface |

| GFH-D507Mo | CO2 | 1.6 2.4 | C:0.12 S:0.45 Mn:0.4 Ni:0.1 Kr:13 Mo:0.01 | 58 | Inokodzera kusevha welding yemavharuvhu ane corrosiveness yakakwira |

| GFH-D547Mo | Manual tsvimbo | 2.6 3.2 4.0 5.0 | C:0.05 Mn:1.4 Si:5.2 P:0.027 S:0.007 Ni:8.1 Cr:16.1 Mo:3.8 Nb:0.61 | 46 | Inokodzera tembiricha yakakwira, high pressure valve sufacing welding |

More information send to E-mail: export@welding-honest.com

Nguva yekutumira: Zvita-26-2022