I. Muchidimbu

Nekukurumidza kusimudzira kwekugadzirwa kwemaindasitiri emuchina, zvimiro zvakashongedzwa zvakaita semazuva ano einjiniya uye midziyo yekumanikidza iri kusimukira yakanangana nekukura uye kureruka maitiro. Izvo zvinodikanwa zvesimbi simba mamakisi zviri kuwedzera uye zvichikwira, kwete chete inoda yakanaka yakazara mekiniki zvivakwa, asiwo yakanaka processability, weldability uye crack resistance.

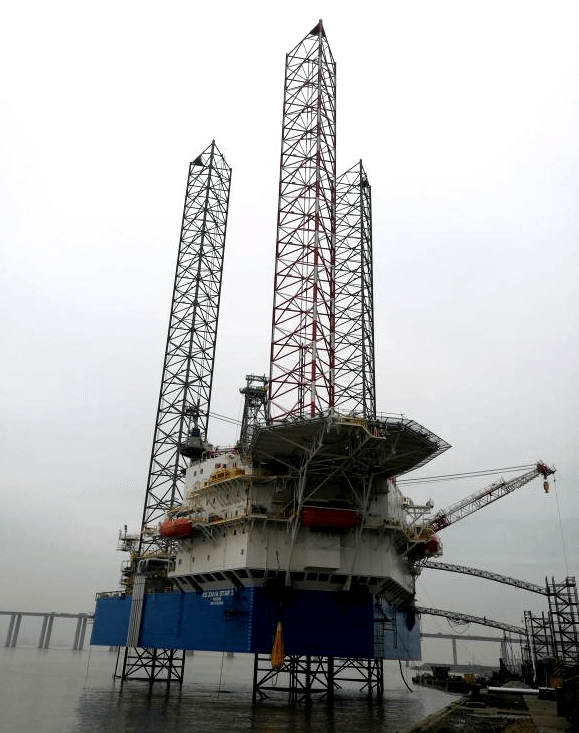

Q690 simbi ndeyepamusoro-simba rakashongedzwa simbi yekuvaka, uko Q inomiririra goho, uye 690 zvinoreva kuti goho resimba i690MPa. 690MPa giredhi simbi ine goho rakawanda uye kusimba kwesimba, uye inoshandiswa zvakanyanya mumichina yekuchera marasha, michina yekuvaka, mainjiniya emugungwa, mapuratifomu ekumahombekombe, midziyo yekumanikidza, nezvimwewo, zvinoda simbi kuti ive nesimba regoho rakawanda uye kupera simba, kusimba kwakanaka, Kutonhora. formability uye yakanakisa weldability.

2.Brief sumo yeQ690 steel plate

| International Q690 simbi giredhi | Q690A | Q690B | Q690C | Q690D | Q690E | Q690F |

| Feather | Hot rolled | Kudzima + kudziya (kudzima uye kushatirwa mamiriro) | ||||

| Kusachena kwemukati | Pamusoro P/S | yakaderera P/S | Minimum P/S | |||

| Zvinodiwa Zvinovhundutsa | NO | Normal tembiricha kuvhunduka | 0℃ | -20 ℃ | -40 ℃ | -60 ℃ |

Nekudaro, parizvino, iyo 690MPa simbi ndiro yemidziyo yekumanikidza yemumba inonyanya kuenderana neEuropean standard EN10028-6, uye zvivakwa zvakakodzera zvakanyorwa muchidimbu mune inotevera tafura:

| Goho 690MPA simbi yeEuropean standard pressure equipment | P690Q | P690QH | P69QL1 | P69QL2 |

| Feather | zviyo zvakanaka zvakadzimwa uye simbi inodziya | |||

| simba rinodiwa | Goho≥690MPa(ndiro ukobvu≤50mm) Tensile770-940MPa | |||

| Kusachena kwemukati | P≤0.025%,S≤0.015% | P≤0.02%,S≤0.010% | ||

| Zvinodiwa Zvinovhundutsa | 20℃≥60J | 20℃≥60J | 0℃≥60J | -20℃≥40J |

| 0℃≥40J | 0℃≥40J | -20℃≥40J | -40℃≥27J | |

| -20℃≥27J | -20℃≥27J | -40℃≥27J | -60℃≥27J | |

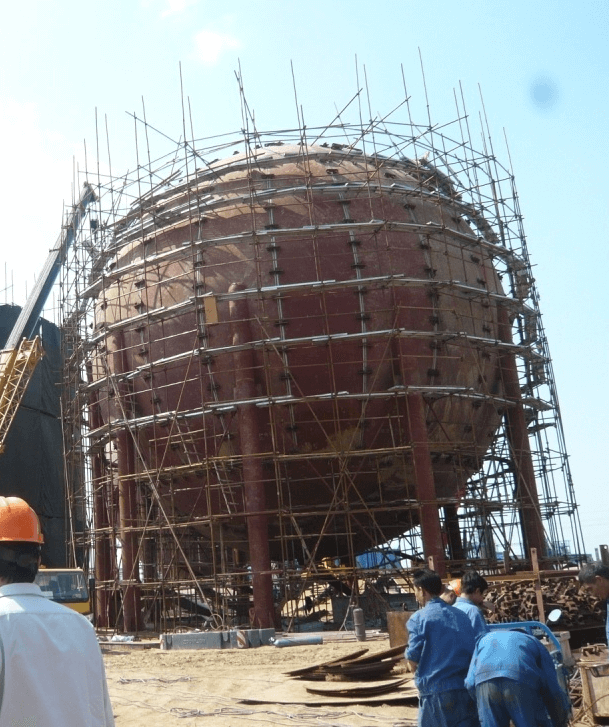

| Main application nzvimbo | Zvimiro zvinotakura kudzvanya kana midziyo yekumanikidza ine yakaderera maitiro kuomarara zvinodiwa | Spherical tank ine yakakwirira tekinoroji zvinodiwa | Liquefied gas marine liquid tank | |

Sendiro yesimbi yematangi ekuchengetera uye simba rekumanikidza, inofanirwa kunge iine simba rakanaka uye kuoma, kutonhora kwekukotama kuita uye kushomeka kwekunzwa. Kunyangwe iyo yakadzimwa uye yakapfava Q690 simbi ine yakaderera kabhoni yakaenzana uye yakanyatso kurongeka zvivakwa, ichine kumwe kuomesa maitiro kana ichienzaniswa nemamwe 50/60kg ekumanikidza midziyo simbi, uye post-weld kupisa kurapwa kunodiwa. Nekudaro, huwandu hukuru hwezvidzidzo zvekuyedza zvakaratidza kuti kune Q690 simbi inobatisa zvinobatika, iyo yakaderera-tembiricha kukanganisa kuoma kuchadzikira zvakanyanya mushure mekushushikana kwekunetseka kwekupisa kurapwa, uye nekuwedzera kwekushisa kwekushisa kwekushisa uye kuderera kwetembiricha yekukanganisa, kudzikira. ye welding consumable toughness ichave iri pachena. Nokudaro, zvakakosha zvikuru kukudziridza kusimba kwepamusoro-soro, kusimba kwepamusoro-soro, uye kupisa-kupisa kwesimbi yeQ690 simbi kuti ibudirire kuisa Q690 simbi kumidziyo inotakura, kuderedza simbi, uye kuderedza mari yekugadzira.

3.Kusuma kupfupi kweQ690 simbi yedu welding tsvimbo

| Item | Standard | Ganda rudzi | Polarity | main features |

| GEL-118M | AWS A5.5 E1108MISO 18275-BE7618-N4M2A | Iron poda yakaderera hydrogen mhando | DC+/AC | Simba rakakwirira, yakaderera haidrojeni, yakakwirira deposition kunyatsoita, yakagadzikana michina zvivakwa, yakanakisa yakaderera tembiricha kukanganisa kuoma pa -50 ° C, uye yakanaka kukanganisa kuoma pa -40 ° C mushure mekupisa kurapwa. |

| GEL-758 | AWS A5.5 E11018-GISO 18275-BE7618-G A | Iron poda yakaderera hydrogen mhando | DC+/AC | Ultra-yakaderera haidrojeni, yakakwira deposition kunyatsoita, kusimba kwakanyanya (-60 ℃≥70J), yakanaka kukanganisa kuoma pa -40/ -50 ℃ mushure mekupisa kurapwa. |

| GEL-756 | AWS A5.5 E11016-GISO 18275-BE7616-G A | Yakaderera hydrogen potassium mhando | AC/DC+ | Ultra-yakaderera hydrogen, AC/DC+ mbiri-chinangwa, yakanyanya kusimba kusimba (-60 ℃≥70J), yakanaka kukanganisa kuoma pa -50/ -60 ℃ mushure mekupisa kurapwa. |

4.Q690 simbi welding tsvimbo mechanical performance display

| Item | As-welded mechanical properties | ||||||

| Ipa MPA | Tensile MPA | Wedzera % | Impact pfuma J/℃ | Radiographic bvunzo | Diffusible hydrogen Ml/100g | ||

| -50 ℃ | -60 ℃ | ||||||

| AWS A5.5 E11018M | 680- 760 | ≥760 | ≥20 | ≥27 | - | I | - |

| ISO 18275-B E7618-N4M2A | 680- 760 | ≥760 | ≥18 | ≥27 | - | I | - |

| GEL-118M | 750 | 830 | 21.5 | 67 | 53 | I | 3.2 |

| AWS A5.5 E1101X-G | ≥670 | ≥760 | ≥15 | - | - | I | - |

| ISO 18275B E761X-GA | ≥670 | ≥760 | ≥13 | - | - | I | - |

| GEL-758 | 751 | 817 | 19.0 | 90 | 77 | I | 3.4 |

| GEL-756 | 764 | 822 | 19.0 | 95 | 85 | I | 3.6 |

Enzanisirai:

1. "X" yakanyorwa nemavara matsvuku muAmerican Standard uye European Standard inomiririra rudzi rweganda rezvinodhaka.

2. GEL-758 inoenderana neE11018-G uye ISO 18275-B E7618-G A muAWS uye ISO zviyero zvakateerana.

3. GEL-756 inoenderana neE11016-G uye ISO 18275-B E7616-G A muAWS uye ISO mitemo maererano.

Mechanical zvimiro zveQ690 simbi welding tsvimbo mukupisa kurapwa mamiriro

| Item | Mechanical properties yemamiriro ekupisa | ||||||

| Ipa MPA | Tensile MPA | Wedzera % | Impact pfuma J/℃ | Kupisa ℃*h | |||

| -40 ℃ | -50 ℃ | -60 ℃ | |||||

| Chinangwa cheprojekiti | ≥670 | ≥760 | ≥15 | ≥60 | ≥52 | ≥47 | 570*2 |

| GEL-118M | 751 | 827 | 22.0 | 85 | 57 | - | 570*2 |

| GEL-758 | 741 | 839 | 20.0 | 82 | 66 | 43 | 570*2 |

| GEL-756 | 743 | 811 | 21.5 | 91 | 84 | 75 | 570*2 |

Enzanisirai:

1. AWS uye ISO inoenderana zviyero hazvina kupisa kurapwa kwekuita zvinodiwa kune zvigadzirwa zviri pamusoro. Mishonga yekupisa iri pamusoro inopfupikiswa zvichienderana nehunyanzvi mamiriro evatengi vazhinji uye ndeyekutarisa chete.

2. GEL-118M ine simba rekuita rakanakisa pa -40 ° C mushure mekurapwa kwekupisa, uye kuderera kwemhedzisiro pa -50 ° C kunonyanya kuoneka.

3. Mushure mekurapwa kwekupisa, GEL-758 ine simba rekuita rakanakisa pa -40°C, kusimba kwesimba pa -50°C, uye kuderera kuri pachena pakupisa kwakaderera pa -60°C.

4. Iko kuderera-kupisa kunokonzera kuoma kwekuoma kweGEL-756 mushure mekupisa kwekupisa kunenge kuduku, uye kutonhora kwepasi-kuoma pa -60 ° C kuchiri kwakanaka.

Weldability kuratidzira kweQ690 simbi welding tsvimbo

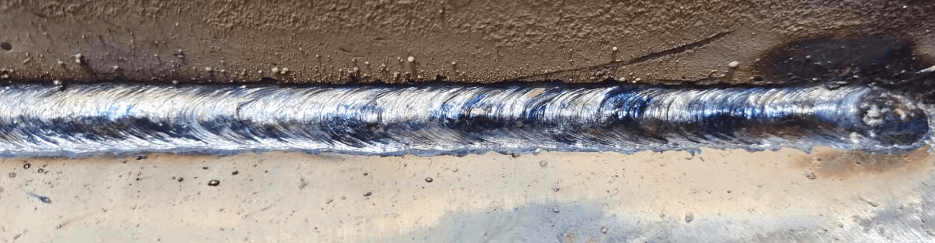

1.Flat fillet welding (φ4.0mm)

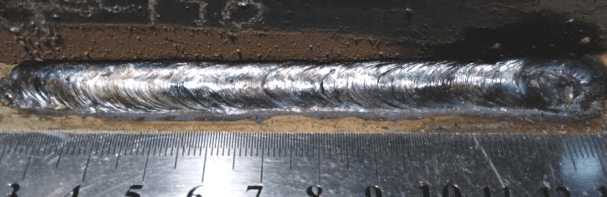

GEL-118M flat fillet welding pamberi uye mushure mekubviswa slag (DC+)

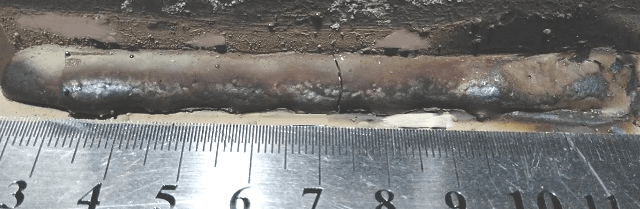

Pamberi uye mushure meGEL-758 flat fillet welding slag kubviswa (DC+)

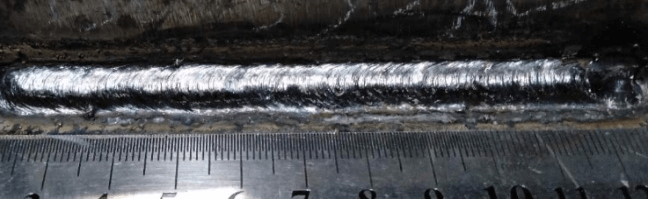

GEL-756 flat fillet welding pamberi uye mushure mekubviswa slag (AC)

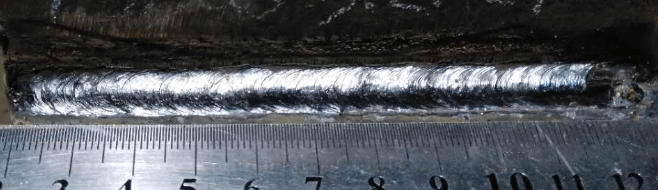

GEL-756 flat fillet welding pamberi uye mushure mekubviswa slag (DC+))

Q690 simbi welding tsvimbo welding precautions

1. Kuchengetedzwa kwewelding zvinodyiwa:

Welding consumables inokurudzirwa kuti ichengetwe pasi pekushisa nguva dzose uye mamiriro akaoma, uye kuiswa pamapuranga kana masherufu, kudzivisa kutarisana zvakananga nemadziro uye pasi.

2. Kugadzirira usati welding:

Nyatsobvisa unyoro, ngura, mavara emafuta, nezvimwewo pamusoro pezvinhu zvepasi, uye dzivisa hunyoro hwepamusoro kana kutarisana nemvura nechando.

3. Matanho anodzivirira mhepo:

Kana welding, inofanirwa kuve nechokwadi kuti iyo yakanyanya mhepo yekumhanya panzvimbo yewelding haipfuuri 2m / s. Kana zvisina kudaro, matanho ekudzivirira anofanira kutorwa.

4. Preheating:

Zvinokurudzirwa kushandisa magetsi ekupisa midziyo yekupisa iyo workpiece kusvika pamusoro pe 150 ° C isati yave welding. Kunyange tisati tack welding, inofanira kupiswa kusvika pamusoro pe150 ° C.

5. Layer uye nzira yekudzora tembiricha:

Munguva yese yewelding process, tembiricha yeinterpass haifanire kunge yakaderera pane preheating tembiricha, uye inokurudzirwa yekupfuura tembiricha i150-220 ° C.

6. Hydrogen kubviswa mushure mekugadzira:

Mushure mekunge weld seam yaiswa weld, pakarepo wedzera tembiricha yekudziya kwemagetsi kusvika 250 ℃ ~ 300 ℃, chengeta ichidziya kwemaawa maviri kusvika mana, uye wozotonhorera zvishoma nezvishoma.

① Kana ukobvu hwechishandiso chiri ≥50mm, nguva yekubata inofanira kuwedzerwa kusvika kumaawa 4-6, yozotonhodzwa zvishoma nezvishoma.

② Pasi pemamiriro ehukuru hwakakura uye kuzvidzora kwakakura, imwezve dehydrogenation inogona kuwedzerwa mushure mekugadzira kusvika ku 1/2 ukobvu, uye zvishoma nezvishoma kutonhora kusvika kune interpass tembiricha.

7. Floor marongero:

Inokurudzirwa kushandisa multi-layer uye multi-pass welding, uye welding speed inofanira kuchengetwa nguva dzose.

More information send to E-mail: export@welding-honest.com

Nguva yekutumira: Jan-10-2023