I. Muchidimbu

Nekukurumidza kusimudzira kwemakemikari epasirese uye simba logistics, Stainless simbi yekuchengetera matangi uye midziyo inoshandiswa zvakanyanya mukutakura uye kuchengetedza kemikari, chikafu nechinwiwa, simba nezvimwe zvinhu. Nekuda kwekusimba kwayo kwakadzika tembiricha uye kumira kwakanaka kwekuora, austenitic simbi isina tsvina inoshandiswa zvakanyanya mukuvaka matangi ekuchengetedza cryogenic, zvishandiso uye zvimiro zvakakura zve cryogenic.

Cryogenic storage tank

2.Muchidimbu sumo yedu -196 ℃ yakaderera tembiricha inokanganisa Stainless simbi welding zvinodyiwa.

| Category | Zita | Model | Standard | Remark | |

| GB/YB | AWS | ||||

| Electrode | GES-308LT | A002 | E308L-16 | E308L-16 | -196℃≥31J |

| Flux waya | GFS-308LT | - | TS 308L-F C11 | E308LT1-1 | -196℃≥34J |

| Waya yakasimba | GTS-308LT (TIG) | - | H022Cr21Ni10 | ER308L | -196℃≥34J |

| GMS-308LT (MIG) | - | H022Cr21Ni10 | ER308L | -196℃≥34J | |

| SAW | GWS-308/ GXS-300 | - | S F308L FB-S308L | ER308L | -196℃≥34J |

3.Yedu electrode GES-308LT (E308L-16)

Kuti ikwane kudiwa kwemusika, kambani yedu yakagadzira akasiyana tembiricha yakaderera-yakadzika, yakanyanya kuomarara austenitic simbi isina maelectrodes, kemikari yesimbi yakaiswa (sezvinoratidzwa muTebhurari 1) uye yakagadzikana michina zvivakwa (sezvinoratidzwa muTable. 2), uye ine yakanakisa yese-chinzvimbo welding process Kuita, uye yakanakisa yakaderera tembiricha kukanganisa kuoma, kukanganisa kwehuwandu hwayo hweferrite pane kukosha kwekuita (Tafura 3).

1.Chemical kuumbwa kwesimbi yakaiswa

| E308L-16 | C | Mn | Si | P | S | Ni | Cr | Mo | Cu | N | Fn |

| NB (%) | 0.04 | 0.5-2.5 | 1.0 | 0.030 | 0.020 | 9.0-12.0 | 18.0-21.0 | 0.75 | 0.75 | - | - |

| Muenzaniso1 | 0.022 | 1.57 | 0.62 | 0.015 | 0.006 | 10.25 | 19.23 | 0.020 | 0.027 | 0.046 | 6.5 |

| Muenzaniso2 | 0.037 | 2.15 | 0.46 | 0.018 | 0.005 | 10.44 | 19.19 | 0.013 | 0.025 | 0.45 | 3.8 |

| Muenzaniso3 | 0.032 | 1.37 | 0.49 | 0.017 | 0.007 | 11.79 | 18.66 | 0.021 | 0.027 | 0.048 | 0.6 |

Tafura 1

2.Mechanical zvinhu zvesimbi yakaiswa

| E308L-16 | Yield MPa | Tensile MPa | Elongation % | -196℃kupa J/℃ | GB/T4334-2020 E Intergranular corrosion | Radiographic kuongorora | Remark | |

| Single value | Avhareji kukosha | |||||||

| NB | - | 510 | 30 | - | - | - | I | - |

| Muenzaniso1 | 451 | 576 | 42 | 32/32/33 | 32.3 | qualified | I | - |

| Muenzaniso2 | 436 | 563 | 44 | 39/41/39 | 39.7 | qualified | I | - |

| Muenzaniso3 | 412 | 529 | 44.5 | 52/53/55 | 53.3 | qualified | I | - |

Tafura 2

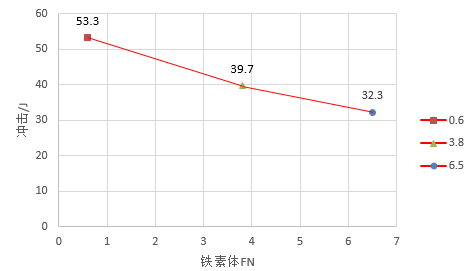

3.Mugumisiro wehuwandu hwekuiswa kwesimbi ferrite pamigumisiro

4.Kuratidza welding process (φ3.2mm)

Welding yakatwasuka pamberi uye mushure mekubviswa slag (DC+)

Pipeline welding pamberi uye mushure mekubviswa slag (DC+)

4. Chengetedzo ye vertical welding

1. Low current welding inofanira kushandiswa;

2. Chengeta arc yakaderera sezvinobvira;

3. Apo arc inotenderera kumativi ose e groove, mira kwekanguva, uye hupamhi hwekuzununguka hunodzorwa mukati me3 nguva yehupamhi hwe electrode.

5.Pipeline mufananidzo we welding consumables application

Kune -196 ℃ yakaderera-tembiricha inokanganisa simbi isina simbi inobatisa, mushure memakore ekutsvagisa uye kugadzirwa kwezvinhu zvinobatisa welding, isu tatova neinowirirana inotsigira welding consumables kune welding tsvimbo, solid cores, flux cores uye akanyura arcs, uye takagadzira ruoko electrode inoenderera arc. welding consumables kune ese-chinzvimbo welding, uye ine akawanda einjiniya application kubudirira, gamuchirai vatengi kubvunza uye kusarudza!

Nguva yekutumira: Zvita-16-2022