Yakaderera-alloy simbi Gasi-yakachengetedzwa ER90S-G simbi Kubatanidza zvinhu

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu |

| GB/T RULES | 0.12 | 0.75-1.50 | 0.30-0.90 | 2.10-2.70 | - | 0.90-1.20 | 0.03 | 0.03 | 0.40 |

| AWS Mitemo | - | - | - | - | - | - | - | - | - |

| MUENZANISO VALUE | 0.075 | 0.85 | 0.60 | 2.5 | 0.03 | 1.00 | 0.01 | 0.005 | 0.05 |

MECHANICAL PROPERTY:

| PROPERTY | KUNYANYA SIMBA(MPa) | KUWEDZERA SIMBA(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | Kurapa kupisa°Cxh | |||||

| GB/T RULES | 540 | 620 | - | 15 | 690*1 | |||||

| AWS Mitemo | 540 | 620 | - | 17 | 690*1 | |||||

| MUENZANISO VALUE | 560 | 640 | 160/0Room tembiricha | 24 | 690*1 | |||||

AKAKUDZWA WEDDING PARAMETERS:

| DIAMETERS ZVINOTAURWA(mm) | 1.0 | 1.2 | 1.6 | |||||||

| ELECTRICITY (Amp) | H/W | 50-220 | 80-350 | 170-550 | ||||||

| O/W | 50-120 | 80-150 | - | |||||||

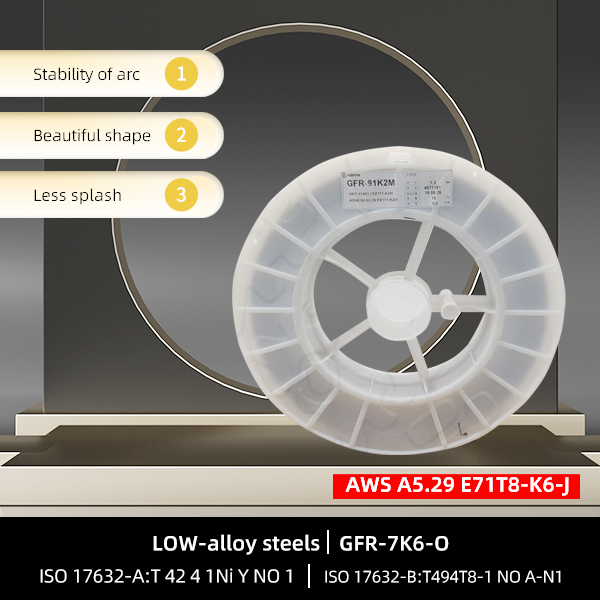

Gasi yakadzivirirwa welding waya yekupisa inopesana nesimbi kirasi 620MPa.

Waya yakatsetseka, arc yakagadzikana, kuumbwa kwakanaka, simbi yakanyungudutswa yakanaka, tekinoroji yewelding yakanaka.

Iyo simbi yakanyungudutswa ine yakanaka mechanical zvivakwa, ine yakanaka porosity kuramba uye weld kuumba.

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu |

| GB/T RULES | 0.12 | 0.75-1.50 | 0.30-0.90 | 2.10-2.70 | - | 0.90-1.20 | 0.03 | 0.03 | 0.40 |

| AWS Mitemo | - | - | - | - | - | - | - | - | - |

| MUENZANISO VALUE | 0.075 | 0.85 | 0.60 | 2.5 | 0.03 | 1.00 | 0.01 | 0.005 | 0.05 |

MECHANICAL PROPERTY:

| PROPERTY | KUNYANYA SIMBA(MPa) | KUWEDZERA SIMBA(MPa) | IMAPACT VALUE J/℃ | ELONGATION(%) | Kurapa kupisa°Cxh | |||||

| GB/T RULES | 540 | 620 | - | 15 | 690*1 | |||||

| AWS Mitemo | 540 | 620 | - | 17 | 690*1 | |||||

| MUENZANISO VALUE | 560 | 640 | 160/0Room tembiricha | 24 | 690*1 | |||||

AKAKUDZWA WEDDING PARAMETERS:

| DIAMETERS ZVINOTAURWA(mm) | 1.0 | 1.2 | 1.6 | |||||||

| ELECTRICITY (Amp) | H/W | 50-220 | 80-350 | 170-550 | ||||||

| O/W | 50-120 | 80-150 | - | |||||||

Nyora meseji yako pano ugotitumira