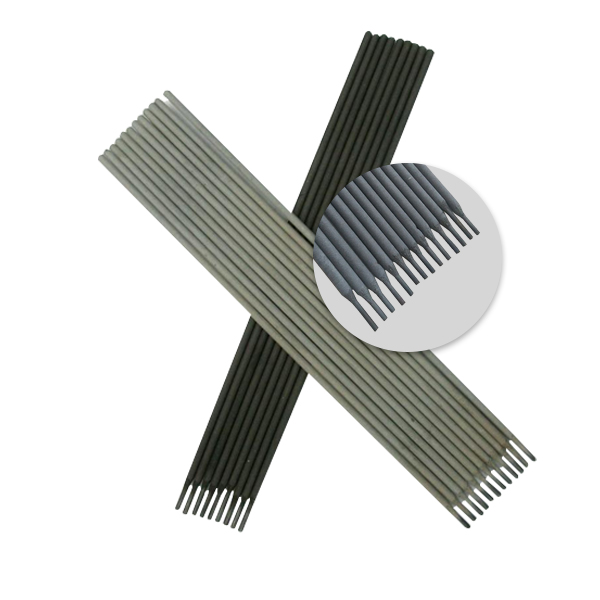

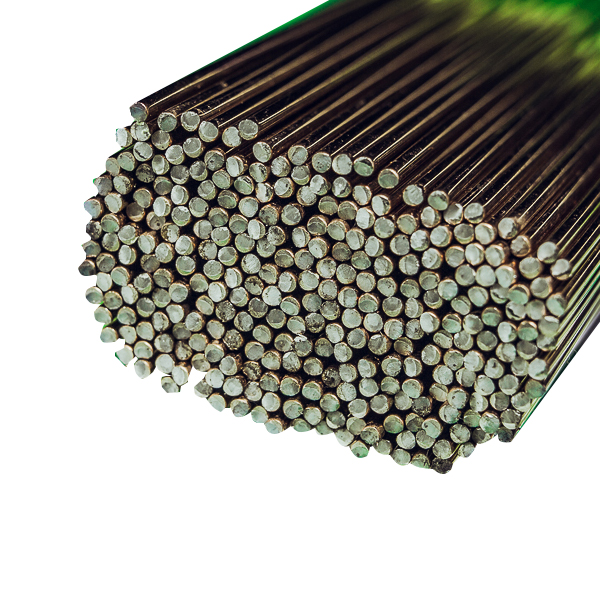

Yakakwira Carbon simbi Manual electrode E9818-G Soldering kugadzira

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu | V |

| GB/T RULES | - | ≥1.00 | ≥0.80 | ≥0.30 | ≥0.50 | ≥0.20 | - | - | ≥0.20 | ≥0.10 |

| AWS Mitemo | - | - | - | - | - | - | - | - | - | - |

| MUENZANISO VALUE | 0.050 | 1.50 | 0.27 | 0.83 | 3.35 | 0.72 | 0.005 | 0.004 | 0.018 | 0.004 |

MECHANICAL PROPERTY:

| PROPERTY | KUNYANYA SIMBA(MPa) | KUWEDZERA SIMBA(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | ELONGATION(%) | |||||

| GB/T RULES | - | - | - | - | - | |||||

| AWS Mitemo | - | - | - | - | - | |||||

| MUENZANISO VALUE | 915 | 992 | - | 65/-20 | 16 | |||||

AKAKUDZWA WEDDING PARAMETERS:

| DIAMETERS ZVINOTAURWA(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | ||||||

| ELECTRICITY (Amp) | H/W | 80-110 | 100-130 | 130-180 | 180-230 | |||||

| O/W | 50-80 | 90-120 | 130-160 | - | ||||||

980Mpa super yakakwirira simba yakaderera ferrohydrogen hupfu mhando yakaderera alloy simbi electrode.

Yakagadzika arc, diki splash, yakanaka slag kubviswa

Yakanakisa yese-chinzvimbo welding performance, yakanaka yakaderera tembiricha kuoma, crack resistance uye yakaderera tembiricha kukanganisa kuoma.

CHEMICAL COMPONET:

| ALLOY(wt%) | C | Mn | Si | Cr | Ni | Mo | P | S | Cu | V |

| GB/T RULES | - | ≥1.00 | ≥0.80 | ≥0.30 | ≥0.50 | ≥0.20 | - | - | ≥0.20 | ≥0.10 |

| AWS Mitemo | - | - | - | - | - | - | - | - | - | - |

| MUENZANISO VALUE | 0.050 | 1.50 | 0.27 | 0.83 | 3.35 | 0.72 | 0.005 | 0.004 | 0.018 | 0.004 |

MECHANICAL PROPERTY:

| PROPERTY | KUNYANYA SIMBA(MPa) | KUWEDZERA SIMBA(MPa) | HEATTREAMENT℃xh | IMAPACT VALUE J/℃ | ELONGATION(%) | |||||

| GB/T RULES | - | - | - | - | - | |||||

| AWS Mitemo | - | - | - | - | - | |||||

| MUENZANISO VALUE | 915 | 992 | - | 65/-20 | 16 | |||||

AKAKUDZWA WEDDING PARAMETERS:

| DIAMETERS ZVINOTAURWA(mm) | 2.6*350 | 3.2*350 | 4.0*400 | 5.0*400 | ||||||

| ELECTRICITY (Amp) | H/W | 80-110 | 100-130 | 130-180 | 180-230 | |||||

| O/W | 50-80 | 90-120 | 130-160 | - | ||||||

Nyora meseji yako pano ugotitumira